Image source: IOCB Prague

News • Photoprintable radiopaque hydrogels

Improved materials for reconstructive and plastic surgery

Researchers from IOCB Prague and Ghent University have been working on improving the properties of gelatin-based materials, thereby expanding the possibilities of their use mainly in medicine.

In a paper published in ACS Applied Engineering Materials, they have presented 3D-printable materials that can be easily monitored using an X-ray machine or through computed tomography (CT).

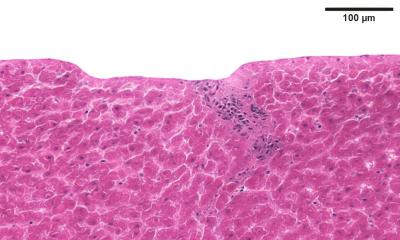

Gelatin-based materials have been a hot topic of research in the last ten years because they are straightforward to produce, non-toxic, inexpensive, biodegradable and - most importantly - because they promote cell growth. For this reason, they are pre-eminently used in plastic and reconstructive surgery. After a surgeon places an implant made of such material into a wound, the body gradually breaks it down and replaces it with tissue of its own. These substances thus accelerate wound healing and even enable the remolding of tissues, for example when performing breast reconstruction after mastectomy. In addition, the materials can be used for 3D printing implants tailored to individual patients.

Photo: Tomáš Belloň / IOCB Prague

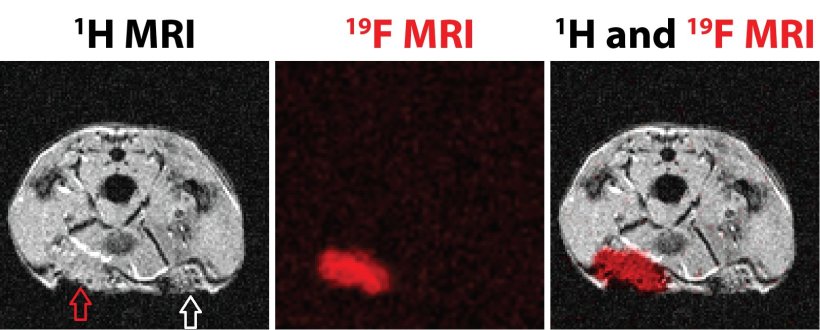

So far, however, there has been one big obstacle to tackle, namely that it has been very difficult to track the breakdown of these materials in the body using conventional imaging methods. And this very hurdle is one that researchers from IOCB Prague are working to overcome. A radiopaque (i.e. X-ray-contrast) agent newly added to the materials makes it possible to trace how quickly implants shrink over time and whether they are intact or damaged.

One person behind this research at IOCB Prague is Ondřej Groborz from the research team of Tomáš Slanina (Photoredox chemistry group). He explains: ‘A whole series of academic papers is being written on this topic. The first of them introduces a gelatin-based material that can be monitored using magnetic resonance imaging. In our second article, recently published in Applied Engineering Materials, we endow the materials with X-ray and CT detectability.’

Because of this improvement, researchers can monitor these implants over time and observe their biodegradation and detect possible mechanical failures. These data are particularly useful in clinical practice. Based on the data obtained, the biodegradation of implants can be tailored to meet specific clinical requirements. This is because tissues in the human body grow at different rates, to which the properties of implants need to be adapted. The goal is to make these implants biodegrade at the same rate as healthy tissue grows.

Ondřej Groborz cooperates on this research with the Polymer Chemistry & Biomaterials Group (PBM) at Ghent University. Belgium is at the forefront in the medical use of implants with this structure. Moreover, the collaboration between IOCB Prague and Ghent University has potential to transcend into the commercial world. The two research institutions have already submitted a joint patent application concerning the use of the described materials in plastic and reconstructive surgery.

Souce: IOCB Prague

26.02.2024