News • Diabetes-related diseases

3D printed implants for personalized treatment of bone defects

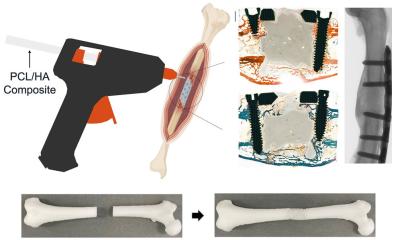

BellaSeno GmbH, a company developing absorbable scaffolds using additive manufacturing technologies, announced a collaboration with Charité – Universitätsmedizin Berlin under the recently established SyMBoD consortium. Under the agreement, BellaSeno will design and manufacture personalized, 3D-printed, absorbable implants suitable for the treatment of diabetes patients with bone defects.

The goal is to restore blood supply and facilitate the regeneration of persistent bone defects that do not heal otherwise. The consortium is an interdisciplinary project covering innovative digital technology based on systems medicine and precise, reproducible additive manufacturing. Within the consortium, BellaSeno is fully responsible for ISO 13485-compliant, medical-grade scaffold manufacturing.

Image source: Shutterstock/Alex Mit

“Current research suggests that 3D-printed scaffolds, which have been optimized mechanically and biologically, can improve bone regeneration,” said Dr. Navid Khani, Head of R&D of BellaSeno. “Our custom-made, high-speed additive manufacturing platform is very precise, generates highly reproducible structures and has been certified according to ISO 13485 standard. We are therefore very well positioned to produce state-of-the-art, medical-grade scaffolds for a variety of applications. This is the first project underlining our manufacturing capabilities for external industry and academic partners.”

“We have selected BellaSeno because of the team's unique expertise in additive manufacturing of porous structures with extremely small features as required for our intended application,” said Dr. Su Ping Patrina Poh of Charité's Julius Wolff Institute (JWI). “This strategic inclusion of BellaSeno is also driven by the fact that, to our knowledge, they are the only company within Germany with the capability to perform the entire additive design and manufacturing process chain with ISO13485 certified processes, which is highly aligned with our intention of clinical translation in the future.”

Recommended article

News • Biocompatible alternative

Non-silicone breast implant to enter clinical trial

Surgery complications, implant rupture, tissue contractures or even plain immune intolerance – silicone breast implants can cause a variety of unfavourable conditions. Because of this, many women think twice about breast augmentation. A new kind of implant might change this up a bit. BellaSeno GmbH, a company developing absorbable implants using additive manufacturing technology, now announced…

BellaSeno is producing 3D-printed absorbable implants in very high-resolution lattice-based structures using melt-extrusion technology. While numerous companies can manufacture porous structures using 3D-printing technologies, it is extremely challenging to reproducibly generate structures if the required unit-cell size is less than 3 mm. Using its custom-built Yasham additive manufacturing platform, BellaSeno can reproducibly and routinely manufacture scaffolds with unit cell sizes down to about 1 mm.

The SyMBoD consortium consists of 4 universities and 1 industry partner and is dedicated to developing novel, personalized treatments for endogenous bone regeneration in patients with diabetes. Funded by Germany's Ministry for Education and Research (BMBF) and led by Charité Universitätsmedizin Berlin, the project includes partner institutions such as University of Freiburg, Fraunhofer IZI, Technical University of Munich, and Genvention GmbH. SyMBoD is part of BMBF's e:Med initiative, which is supporting various system medicine consortia with a total budget of EUR 200 million over the course of eight years.

Source: BellaSeno

26.03.2020