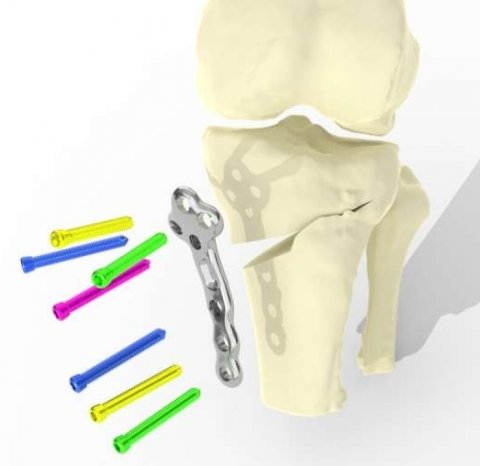

News • Titanium-alloy knee plates

3D printing simplifies high tibial osteotomy

3D metal printing technology is producing personalised medical-grade titanium-alloy plates that perfectly fit individuals suffering arthritis of the knee.

Image credit: University of Bath

Engineers at the University of Bath’s Centre for Therapeutic Innovation (CTI) working with 3D Metal Printing Ltd, are using the TOKA (Tailored Osteotomy for Knee Alignment) treatment to improve the surgical procedure and fit of high-tibial osteotomy (HTO) plates to realign a patient’s knee. The system improves stability, comfort and weight bearing over existing generic plates. The technique also simplifies high tibial osteotomy (HTO), making operations quicker and safer.

The HTO plates have been safety tested in a computer-based virtual ‘in-silico’ trial using CT scan data from 28 patients. The in-silico clinical trial, globally the first to demonstrate the safety of an orthopaedic device, modelled the stresses that would be exerted on the bespoke plates and showed these would be comparable in safety to the standard treatment.

‘Knee osteoarthritis is a major health, social and economic issue and does not receive as much attention as it should,‘ Professor Richie Gill, from the Centre for Therapeutic Innovation, pointed out. ‘A quarter of women over 45 have it, and about 15 percent of men, so it’s a significant burden that many live with. Knee replacement is only useful for end-stage osteoarthritis, so you can be in pain and have to live with a disability for a long time, potentially decades, before it’s possible. We hope that the new TOKA process we’ve developed will change that.‘

Knee osteoarthritis patients receiving TOKA treatment will undergo a 3D CT scan of their knee, before a personalised 3D printed surgical guide and plate, both shaped to their tibia (shin bone), is created. The surgical guide simplifies the surgery and is designed to improve accuracy. The process also sees the first implementation of 3D printed screw threads into the HTO plates, meaning they can be optimally positioned to help secure them against the bone.

3D printing the custom knee implant and doing the scanning before operating means surgeons will know exactly what they’ll see before operating and where the implant will go

Richie Gill

When clinical centres return to carrying out elective surgery, expected later this year, trials will begin. UK hospitals in Bath, Bristol, Exeter and Cardiff will take part in a randomised control trial to compare patient outcomes with an existing generic HTO procedure. Tests of the TOKA technique have already begun in Italy where, so far, 25 patients received new personalised HTO plates as part of a trial at the Rizzoli Institute in Bologna.

HTO surgery realigns the knee joint by making a cut to the tibia and opening a small gap, which needs to be stabilised by a metal plate. This realignment moves the loading to a less worn part of the knee. Patient outcomes depend on how accurately the cut is made and the gap opened. ‘HTO surgery has a long clinical history and has very good results if done accurately. The difficulty surgeons have is achieving high accuracy, which is why we have created the TOKA method,’ Gill explained. ‘This starts with a CT scan and digital plan. 3D printing the custom knee implant and doing the scanning before operating means surgeons will know exactly what they’ll see before operating and where the implant will go. In addition to a surgeon being able to precisely plan an operation, a surgical guide (or jig) and a plate implant, each personalised to the patient, can be 3D printed automatically, based on the scanning data. Importantly this type of treatment relieves the symptoms of knee osteoarthritis while preserving the natural joint.’

Pre-planning greatly simplifies surgery and could cut time on the operating table from two hours to around 30 minutes.

Source: University of Bath

31.08.2021