News • Biocompatible alternative

Non-silicone breast implant to enter clinical trial

Surgery complications, implant rupture, tissue contractures or even plain immune intolerance – silicone breast implants can cause a variety of unfavourable conditions. Because of this, many women think twice about breast augmentation. A new kind of implant might change this up a bit.

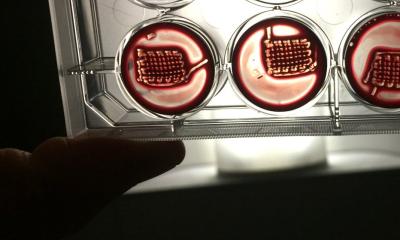

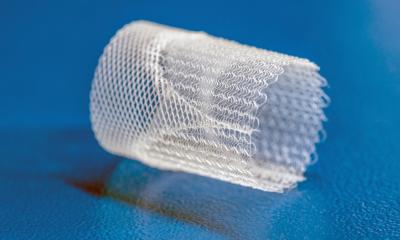

BellaSeno GmbH, a company developing absorbable implants using additive manufacturing technology, now announced it obtained full ISO 13485 certification for its design and additive manufacturing processes, ranging from the concept and prototype to the production of novel, non-silicone-based absorbable implants. In addition, the company raised a further EUR 1 million from its existing investors, bringing the total amount raised by BellaSeno to EUR 4.2 million. The proceeds will be used to fund a clinical trial of Senella, its first product, a biocompatible and fully absorbable breast scaffold made from a polymer that is FDA-approved and CE-marked for a wide variety of clinical applications. The trial is scheduled to start in Q4/2019.

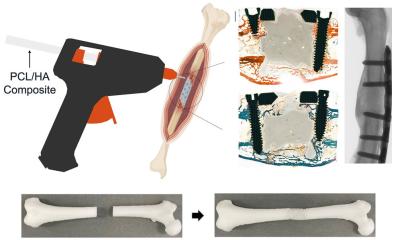

“We are now one of very few companies worldwide with an ISO 13485 certification covering the entire process of design and additive manufacturing of absorbable implants,” said Dr. Simon Champ, CEO of BellaSeno. „This is not only a prerequisite for the clinical trial of Senella, our first product, but also for closing contract manufacturing deals with companies seeking to develop and market their own absorbable implants for a wide range of medical applications. We are offering the entire process under ISO 13485 certification to other medtech companies worldwide – from concept and inhouse design to manufacturing of prototypes, clinical trials and series production.” He added that BellaSeno’s platform technology and patent-pending porous architectures can be used to design and manufacture a broad spectrum of soft and stiff devices for bone and soft tissue replacements.

Recommended article

News • New FDA info

Can breast implants increase lymphoma risk?

The FDA has been closely tracking the relationship between breast implants and a rare type of non-Hodgkin's lymphoma since we first identified this possible association. We’ve been working to gather additional information to better characterize and quantify the risk so that patients and providers can have more informed discussions about breast implants,” said Binita Ashar, M.D., director of…

Absorbable implants guide the growth of natural tissue derived from the patient's own body and are slowly, but fully absorbed over a period of several days, months or years, dependent on the composition of the polymer employed. In contrast to many other implants, the result is a natural tissue with no foreign body remnants. BellaSeno’s implants are produced via additive manufacturing (AM), more commonly known as 3D-printing. The company believes their product has the potential to disrupt the current breast surgery markets, which at present are dominated by silicone implants.

Source: BellaSeno

09.08.2019