Photo: Laboratory of Metal Physics and Technology / Complex Materials / ETH Zurich

News • Let it grow

3D printed templates for bone implants made of salt

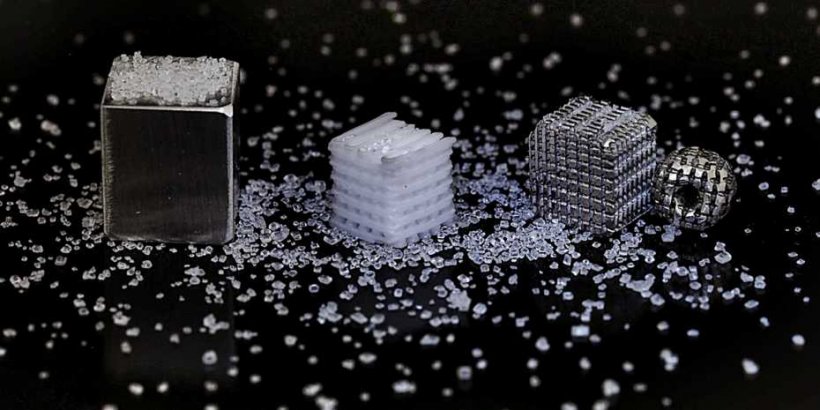

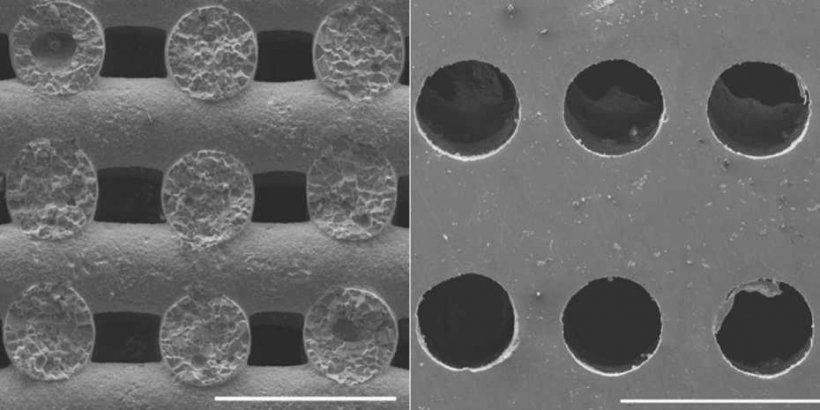

With the help of a 3D printed salt template, researchers from ETH Zurich have succeeded in producing magnesium scaffolds with structured porosity that are suitable for bioresorbable bone implants.

For the treatment of complex bone fractures or even missing bone parts, surgeons typically deploy metal implants. In this context, an attractive alternative to the traditional materials like bioinert titanium are biodegradable magnesium and its alloys. Implants made of the latter light metal are advantageous because they can biodegrade in the body, which can absorb magnesium as a mineral nutrient, rendering a second surgery for implant removal unnecessary. To promote rapid healing, the design of implants or their surfaces should be directed towards promotion of cellular adhesion or even in-growth. Materials researchers from the Laboratory of Metal Physics and Technology and the Complex Materials Group at ETH Zurich have therefore collaborated to develop a new procedure for the manufacture of magnesium implants that contain numerous structurally ordered pores but still retain their mechanical stability. This development is the subject of a forthcoming article in Advanced Materials.

Scaffolds made of magnesium

The infiltrates obtained in this way are mechanically very stable and can be easily polished, turned and shaped

Jörg Löffler

To create a porous structure the researchers first printed a three-dimensional salt template using a 3D printer. Because pure, standard table salt is not suitable for printing, they developed a gel-like salt paste for this purpose. The strut diameters and spacings of the salt template can be tailored by the printing process. To gain sufficient mechanical strength the salt structure was subsequently sintered. During sintering the fine-grained materials are heated significantly, while the temperature is chosen safely below the paste’s melting point to retain the structure of the workpiece.

The next step was to infiltrate the pores with magnesium melt. “The infiltrates obtained in this way are mechanically very stable and can be easily polished, turned and shaped,” says Jörg Löffler, Professor of Metal Physics and Technology in the Department of Materials. After mechanical shaping the researchers dissolved the salt, leaving a pure magnesium implant with numerous, regularly structured pores.

Photo: Laboratory of Metal Physics and Technology / Complex Materials / ETH Zurich

“The possibility to control the pore size, distribution and orientation in the material is decisive for clinical success, because bone cells like to grow into these pores,” says Löffler. Growth into pores is in turn decisive for the rapid integration of the implant in bone. The new procedure for manufacturing these template structures from salt can be applied to other materials besides magnesium. Co-authors Martina Cihova and Dr Kunal Masania expect that the process can also be used to tailor pore geometries in polymers, ceramics and other light metals.

The idea of this new manufacturing procedure emerged within the framework of the Master’s thesis of Nicole Kleger, whose study was supported by an ETH Zurich Excellence Scholarship & Opportunity stipend. Her work was also awarded with the ETH medal for excellent Master’s theses. Nicole Kleger is now a doctoral student in the Complex Materials Group of ETH professor André Studart, under whose direction the initial salt template was 3D printed. In her doctoral thesis project Kleger is now developing the 3D-printing procedure further.

Source: ETH Zurich

26.08.2019