Article • Guidelines

Reprocessing - staff qualifications are vital

The reprocessing of medical devices in Europe is very inconsistent, according to a European Commission survey that was carried out in the 27 EU member states among politicians, medical device manufacturers and reprocessing companies, as well as doctors, hospitals and related professional parties

Report: Anja Behringer

The survey made it apparent that only half of all countries (46.5%) have legal guidelines for medical device reprocessing. However, this actually does not mean that wherever these legal guidelines are in place disposable medical devices can also be reprocessed. In France, for instance, this is prohibited.

Almost half of those surveyed believed that most disposable medical devices (84%) such as balloon catheters, flexible endoscopes, or instruments for minimally invasive surgery couldn’t be reprocessed without posing health risks for patients. The various disinfection agents have advantages and disadvantages, with an increasing number of patients becoming allergic to some.

Three regulatory classes from A to C

In Germany, guidelines regarding the type of devices and liquids they come into contact with are particularly detailed. According to the Commission for Hospital Hygiene and Infection Prevention at the Robert Koch Institute (KRINKO), medical devices are assigned to three regulatory classes from A to C, with the more complex devices assigned to category C.

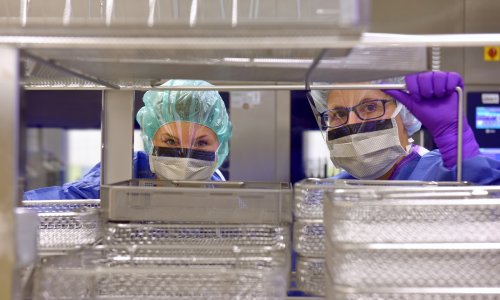

To ensure hospital hygiene for patients and staff, reprocessing of sterile devices is one of the ‘building sites’ where disinfection and sterility are of the utmost importance. This applies to the entire decontamination, cleaning, disinfection and sterilisation through to sterile materials manufacture.

Hygienic reprocessing of medical devices, such as catheters, syringes or endoscopes, can be manual, automatic or semi-automatic. Numerous companies offer sterilisers, or disinfection agents, but their utilisation should be carefully considered due to different effectiveness and particularly due to side effects.

Critical staff qualifications

Flawless hygiene and sterility of medical devices is ensured either by internal hospital staff – although there is no actual, recognised job description for this type of work – or can be out-sourced. Due to a lack of resources and know-how, complex and thermo-sensitive medical devices cannot be reprocessed in the hospital. They must be disposed of and replaced after each one-time use.

Hospital central sterilisation units are being increasingly pushed to their limits by the continuous requirement for investments into new equipment and processes. This must be considered when looking at the possible cost savings achieved through the reprocessing of expensive disposable products because the use of insufficiently reprocessed products can cause infections, repeated hospital stays and therefore additional healthcare costs.

The demands on the staff are also rising, as described by the KRINKO and the Federal Institute for Drugs and Medical Devices (BfArM) in their recommendations in ‘Requirements for Hygiene in the Reprocessing of Medical Devices’ Proving knowledge

Hospital staff must be able to prove knowledge of medical instruments (also department-specific), knowledge of infection prevention and control, and microbiology (including transmission routes), as well as of risk assessments and medical devices classification based on the recommendations.

Key aspects of reprocessing:

- Appropriate preparation (pre-treatment, collection, pre-cleaning, disassembly)

- Cleaning, disinfection, rinsing and drying

- Checking for cleanliness and soundness

- Care and maintenance

- Functional testing

- Labelling

- Packaging and sterilisation

- Documented release of medical devices for use/storage

There are also spatial and organisational aspects to the process, along with the provision of procedural, working and legal instructions.

The documentation states: ‘It is assumed that somebody is suitably qualified if these contents were covered in the course of their recognised training in a respective medical profession and if this training was successfully completed. If the contents were only partially covered during this training, or were not covered based on the most up-to-date guidelines they will have to be covered or brought up to date through the attendance of suitable, further on-the-job training. Without proof of training in a respective medical profession specific training is necessary.’

Quality assurance includes water hygiene

There is no recognised apprenticeship/profession in the reprocessing field. One manufacturer therefore offers an academy for training and advanced training in this subject.

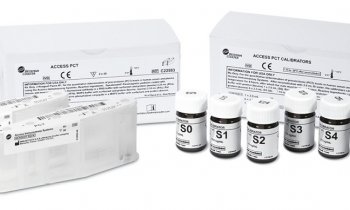

Some manufacturers of flexible endoscopes also carry out hygiene and microbiological examinations as stipulated by the Robert-Koch-Institute and the BfArM during manual and automated reprocessing. Quality assurance not only includes the inspection of medical devices as to potential contamination but also the hygienic innocuousness of water supplies and water used for rinsing. The reprocessing industry claims the savings potential to be up to fifty percent of the original costs of medical devices.

27.10.2016