Confocal microscopy ensures the quality of medical devices

News from COMPAMED Nanofocus AG

Medical products have to fulfil exacting requirements. That is why surface properties are increasingly analysed with optical 3D measurement systems.

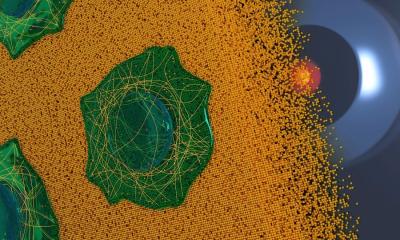

Optical 3D measurement techniques, such as confocal 3D microscopy, offer an alternative to traditional tactile methods that may be imprecise, not suitable for automation or even damage sensitive surfaces. The NanoFocus μsurf system (Oberhausen, Germany) based on optical filtering using a confocal spatial filter (multi-pinhole filter) measures fast and precisely in production environments. Already proven to be a reliable and robust means of measurement in the automobile industry it is now being applied to many different applications, including medical devices as diverse as dental implants and stents.

The high precision piezoelectric actuator for positioning the objective allows roughness measurements in the nanometer range. Extremely rough surfaces with steep edges can also be captured and evaluated. The accuracy and reproducibility of the measurement results is regularly verified based on ISO calibration standards.

Besides the measurement of 3D topography, confocal imaging also allows the calculation of images with infinite depth of focus. The great advantage of this method over classical REM analysis is measurement without a preceding period of preparation this means living cell cultures can also be captured.

For further information see: www.nanofocus.de

20.11.2008