Image source: Fraunhofer IPA

News • A new kind of hearing aid

A 'contact lens' for the ear

Excessive noise, hearing loss, vascular constriction, old age – hearing difficulties can be caused by many factors. To help improve the quality of life of people with hearing impairment, Mannheim start-up Vibrosonic have developed a new hearing aid with an integrated loudspeaker that sits directly on the eardrum.

This hearing contact lens is not an implant, and the sound quality it delivers outperforms other hearing systems currently on the market. Vibrosonic is a spin-off company of the University of Tübingen’s ENT clinic and the Fraunhofer Institute for Manufacturing Engineering and Automation IPA through its Project Group for Automation in Medicine and Biotechnology PAMB.

According to the German association for the hearing impaired – Deutscher Schwerhörigenbund e.V – some 15 million Germans are hard of hearing. In many cases, hearing aids can improve hearing ability and simplify the day-to-day lives of those affected. With most standard hearing devices, the loudspeaker sits inside the wearer's ear canal. This produces acoustic distortions that can impair sound quality. The microphone is positioned behind the ear where it is susceptible to noise interference such as wind. With its innovative hearing solution, Mannheim start-up Vibrosonic are set on resolving these challenges. The company was founded in 2016 by Dr. Dominik Kaltenbacher and Dr. Jonathan Schächtele – former research scientists at the Fraunhofer Project Group PAMB – and Dr. Ernst Dalhoff from the University of Tübingen ENT clinic. Five years on, Vibrosonic employs a staff of 27 today.

Image source: Fraunhofer IPA

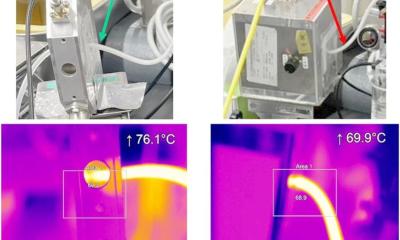

Vibrosonic alpha, the spin-off's first CE-certified hearing solution, consists of three components: the hearing contact lens, an auditory canal module and a behind-the-ear module. The hearing contact lens and auditory canal module remain securely inside the auditory canal; the behind-the-ear module can be removed. With the hearing contact lens, rather than just sitting inside the auditory canal, the loudspeaker is positioned right onto the eardrum. It transmits vibrations to the ossicle directly, with no interference from airborne noise. Sound is transmitted through direct mechanical stimulation of the ear. This helps reproduce the natural hearing process very effectively. The hearing contact lens, loudspeaker and one of the three components of Vibrosonic alpha, is capable of amplifying sounds across the complete audible frequency spectrum, ranging from under 80 Hz to 12 kHz. Conventional systems are not able to do this.

Because of differences in the shape of every eardrum, the hearing contact lens is specifically manufactured for each patient individually. In this process, the Vibrosonic actuator — a piezoelectric micro-loudspeaker — is integrated into a silicon mold. “Because our hearing contact lens is worn directly on the eardrum — just like a contact lens on your eye — very low and particularly high tones can be amplified very effectively, while the lens’ principle prevents disruptive noises caused by feedback. For example low tones are crucial when listening to music, because they make the sound richer. The ability to hear high tones properly is important for speech comprehension, as the coded overtones shape the character of the voice,” Vibrosonic CEO Dr. Dominik Kaltenbacher explains.

Image source: Fraunhofer IPA

With severe hearing loss or extreme miniaturization, conventional hearing aids reach their limits due to feedback and distortion effect – a result of the performance limitations of the coil-based loudspeakers that have been used up to now. “Our hearing contact lens uses the world's first hearing device loudspeaker to have been consistently developed and manufactured based on microsystems engineering methods – the Vibrosonic actuator. The individual structures within the Vibrosonic actuator are a thousand times smaller that the width of a human hair. Despite its very small size, it delivers extraordinary hearing performance,” Kaltenbacher explains.

Initial studies with a small number of participants have shown that the Vibrosonic alpha can improve the hearing experience of people with mild to moderate hearing impairment. The system is suitable for patients over 18 years of age and can be worn on one or both ears, depending on the degree of hearing loss. However, there are plans to reduce the size of the hearing system's current components, such that they fit discretely deep inside the ear channel, where they are invisible from the outside.

Source: Fraunhofer IPA

03.07.2021