Sponsored • X-ray QA

Triple celebrations in Sweden

The Swedish RTI Group reports three notable milestones in 2021, including its 40th year in specialised X-ray safety manufacturing.

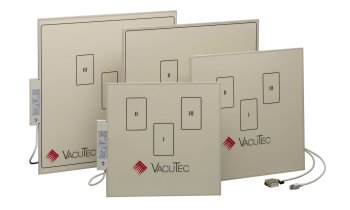

In 1981, the DIGI-X model – the first commercially available multimeter to measure non-invasive kV – was launched. ‘Subsequent developments have included world firsts, in both quality assurance (QA) hard- and software, of the Mini-X, PMX-II, Barracuda and oRTIgo,’ the firm reports. ‘Today, RTI’s trademark Piranha and Cobia meters are used by a plethora of hospitals, major manufacturers of X-ray equipment, service providers and government authorities worldwide.’ Early in 2021, RTI launched its own Scatter Probe, a combined leakage and scatter detector, an upgraded version of its industry-leading QA software Ocean. At the forefront of these key developments in X-ray QA have been Olle Mattsson (Area Sales Manager Nordic & Rest of the World) and Sören Sturesson (Product Management & Technical Manager Calibrations), both RTI’s longest-serving “veterans”, now celebrating 25 years of service in the Gothenburg HQ Sales and R&D departments.

What drew them to RTI?

After graduating as an electrical engineer, Mattsson saw a RTI job advertisement. ‘Like many others, I’d never heard of the concept of measuring on X-ray machines non-invasively. RTI, therefore, sounded like a very open-minded, creative and forward-thinking company.’ The job interview was a resounding success. In the early ’90s, during Sturesson’s studies in Medical Physics at Sahlgrenska University Hospital, Gothenburg, he was working on dosimetry in diagnostic radiology departments. ‘After reading about the X-ray developments at RTI, I applied for work there as part of my master’s thesis evaluating solid-state detectors and scintillating materials for radiation protection in medical X-ray. I graduated in ’95 and worked part-time at the University Hospital and at RTI, before joining the latter full time,’ bringing him understanding and schooling in clinical and manufacturing in dosimetry.

How have RTI’s ‘firsts’ impacted on the X-ray market and influenced your own work?

‘If RTI has been the first to do something, most of my time in Sales has been spent explaining our unique solution,’ Mattsson said. ‘Customers are very keen to get the latest and best on offer. Thanks to RTI, the X-ray QA market has advanced significantly in user-friendliness and meeting new demands. Naturally, this will continue to improve in future.’

Research and development has been challenging, but working with generations of X-ray multimeters has been exciting, Sturesson pointed out. ‘There have been increased demands for user-friendliness to meet the new technical innovations within diagnostic imaging. When the company released DIGI-X in 1981, every X-ray tube/filter combination was almost the same, whereas today there’s a large variety in X-ray spectra, narrow-beam geometry.’

How did the X-ray industry respond to RTI’s breakthrough developments?

‘Due to all its “firsts”, many times our competitors simply had to follow us,’ enthused Mattsson. ‘The Barracuda meter release in 2001 was a major paradigm shift for the X-ray multimeter market,’ Sturesson observed. ‘Our in-depth research and testing resulted in a meter without the shortcomings present in other non-invasive X-ray multimeters then available. Our competitors followed ever since, while we’ve continued to lead in the simplification of using our meters, not least with software tools like Ocean.’

How has X-ray testing technology changed in 25 years?

‘The X-ray machines and QA solutions available have moved the focus away from hardware towards different software solutions to help the users,’ Mattsson explained. ‘Consequently, QA testing standards had to change due to new regulations in the X-ray market, often after the industry has already developed the new hardware to meet demands. In RTI Sales, we have a far bigger and more active global distributor network – more than 100 contacts – since I joined. Since the early 2000s, beginning with the formation of RTI Group Inc. in the USA and, more recently, with Group APAC in Singapore, our presence and exposure in North America and Asia-Pacific also increased significantly.’

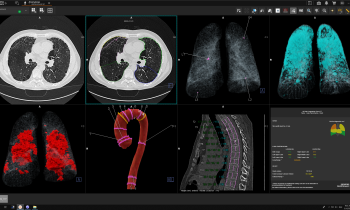

Sturesson: ‘The basics are still the same – safety and proper functionality of the X-ray equipment. The major change was when X-ray film was phased out and replaced with digital detectors, opening the door for major development of X-ray diagnostics, which has led to a wide range of applications with which the X-ray multimeters of today must comply.’

How will the increased implementation of software shape future X-ray QA?

Software will continue to be even more important in supporting the users in their daily QA work, but we will also certainly see new dosimeters on the market that meet new technical demands

Sören Sturesson

‘I don’t think anyone could foresee how big the focus on software would be, nor how many different software programmes would be available today to assist users in so many ways,’ Mattsson noted. ‘Software has become essential, and will continue to grow to ensure compliance, easy management of measurements and the integration of other important data. Therefore, RTI has invested in its Academy training and online presence to increase accessibility of the Ocean software portfolio.’

‘In the late ’80s, RTI launched oRTIgo, the first software tool for X-ray QA,’ Sturesson added. ‘This continued to develop and has now evolved to the Ocean software we offer today. It’s much more than storage of measured data because it provides organisation, compliance and efficiency for the entire X-ray QA process. As an innovative organisation, we are experienced enough to research and develop the rapidly changing software needs of our customers and partners.’

Mattsson: ‘RTI will continue its holistic view and strengthen its focus on complete solutions. Our drive to work even closer together with our distributors and users to be their QA partner will doubtless receive even more interest within the X-ray industry!’

‘RTI’s determination to develop even more efficient QA solutions will be a huge determining factor in our progression,’ Sturesson predicted. ‘Software will continue to be even more important in supporting the users in their daily QA work, but we will also certainly see new dosimeters on the market that meet new technical demands.’

Source: RTI Group

30.09.2021