The promise of proteome analysis

By David Loshak

Non-invasive, quick and painless proteome analysis of urine can identify 17 specific protein fragments to diagnose atherosclerosis more accurately and find new biomarkers for the condition, according to researchers at Freiburg University Hospital in Germany.

The proteome is the entire complement of proteins expressed by a genome, cell, tissue or organism. ‘Collagen forms fibrous caps on the epithelium,’ explained cardiologist Dr Constantin von zur Muehlen. ‘These caps produce collagen fragments and proteomes are high concentrations of those fragments.’ Proteome analysis of urine needs only one sample per patient, he told the American Heart Association in Washington DC. ‘After using mass spectrometry and capillary electrophoresis in one examination to analyse specimens from 67 people and characterise thousands of proteins, we determined that certain protein fragments can be found only in coronary artery disease patients, and they established the proteome pattern. Proteome analysis shows great promise. It is easy to use and shows a high reproducibility.’

When the results were compared to standard coronary angiography X-ray examinations, the urine tests were found to be 84% accurate. That was ‘interesting, but I’d be cautious,’ commented Dr Alan Daugherty, director of the Cardiovascular Research Centre at the University of Kentucky. ‘It would obviously be desirable to be able to diagnose coronary artery disease without an angiogram and there has been a tremendous amount of effort looking for biomarkers. But we’ve been trying to do something like this for decades and a lot of effort is still needed to move the results of the study toward clinical use.’

Although thorough investigation of the entire urinary proteome is unlikely for some years, definition of biomarkers using proteome urinalysis also promises to advance non-invasive diagnosis of kidney diseases and assessment of nephrological prognoses.

The German researchers are now working with a strain of mice genetically engineered to develop coronary artery disease as they age. ‘We found that, the older they are, the more heavily expressed is the proteome pattern,’ Dr Muehlen said, who had hoped to undertake a larger human study but meanwhile more animal work was needed. While unstable collagen was more likely to rupture, blocking an artery completely, it was still not known if stable regions of atherosclerosis produced more collagen than unstable regions.

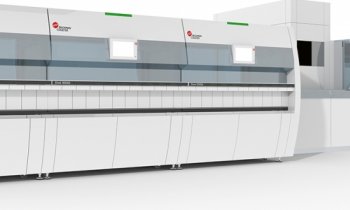

Since the advent of the first automated urine cell analyser in 1995, automated urine testing, including automated microscopy, has become a leading method of diagnosis and screening. Cheap and able to identify many conditions, it is one of the most valuable tools in the medical armamentarium, crucial in detecting urinary tract infections. These are one of the commonest problems doctors encounter, accounting for at least a third of hospital laboratory specimens.

Urinalysis is also of increasing interest to microbiologists. Until recently, urine-screening entailed laborious and time-consuming microscope cell numeration. Today, increasingly, automated urinalysis can provide detailed reports in only two minutes, identifying bacteria and assisting swifter determination of sources of infection.

The fact that analyses are negative in some 70% of cases means that unnecessary tests and other lab work are avoided, significantly improving lab efficiency and lowering costs.

However, hospital and healthcare laboratory clinicians and other workers emphasise that maximally efficient workflow requires not only the information technology and robotics of automated analysers but also substantial input from management science.

Increasingly, laboratories are employing Lean manufacturing principles. Often known simply as ‘Lean’, these consider that the use of resources for any goal other than the creation of value for the end user is wasteful. Lean principles evaluate lab work activities and processes to eliminate waste, variation and procedures that compromise efficiency in terms of cost and speed. Lean optimises flow and, rather than simply accepting current ideas, uses empirical methods to decide what matters. The goal of a Lean laboratory is to use less effort, fewer resources and less time to test incoming samples. By contrast, conventional testing laboratories can suffer from long and variable lead times. Typically, analysts and microbiologists focus on test accuracy and individual test run efficiency. Personnel are dedicated to specific tests but have minimal control of the progress of individual samples through test routing, which can be variable.

In many laboratories, there are queues for each test because individual samples wait until enough similar samples collectively constitute ‘efficient test runs’. That causes long, variable lead times and does not, as intended, assist higher productivity.

Although ‘fast track’ systems seek to deal with urgent samples, these often become unworkable because the proportion of samples given priority is too large. And when labs maintain high levels of ‘work in process’, much non-value adding effort goes into controlling, tracking and prioritising samples and in planning analysts’ work.

For many testing laboratories, the workload has significant peaks, which produce poor lead time performance as well as significant dips, which cause low productivity, and there is no mechanism to level or smooth these out.

Lean labs develop value stream maps to overcome the problem of working on point solutions that merely move bottlenecks from one process to another without delivering improvements generally. Simply reducing lead times in the analytical lab below the time of a release constraint test in the microbiology lab achieves little, if anything.

Lean labs usually have defined sequences of tests and associated analyst roles. Thus, once sample testings begin, they are not held up

in queues between tests but keep moving.

01.09.2009