Speeding up vaccine production

Cell culture technologies are cracking egg dependence. Brenda Marsh reports

During the race to produce vaccines against evolving influenza viruses the slowness of their manufacture has turned producers more sharply towards cell culture technology. Using the traditional process, fertilised chicken eggs must first be inoculated with live flu virus, then the resulting egg-adapted virus must be purified and inactivated to produce trivalent inactivated virus (TIV), during this laborious process.

Cell culture technology, first used to produce a polio vaccine 56 years ago, but which has developed far more over the past three decades*, is a far quicker production option and has other advantages.

Mammalian cells

Rather than eggs, many firms now use mammalian cells to culture their flu vaccines, for example Novartis and Solvay have worked with the Madin-Darby canine kidney cells, Baxter with a primate kidney cell line and Sanofi-Pasteur and Crucell have worked with the human cell line. In this process, a live flu virus is introduced to the cells in culture; after the viral infection has proliferated among those cells the live virus is harvested and inactivated, as in egg-based flu vaccine production. Among the drawbacks: To meet full production, a sufficient seed stock of the live virus is needed and so, therefore, are high-containment facilities.

Genetic engineering

Ways to avoid the need for a seed stock have emerged, for example by producing genetic sequences that code for antigens on a virus surface and not the live virus itself. Because those resulting strain-specific sequences do not produce infectious virus, having a high-containment facility is unnecessary. Also, the time needed to produce and begin manufacturing them can be just weeks or months fewer than is needed to establish a supply of live viral seeds. Along with these, benefits include lower cost, possibly easier licensing and, most importantly, quicker production to meet the demands of a potential pandemic.

Insect cells and baculovirus

The use of baculovirus and insect cell technology has proved an attractive option for many vaccine producers, and scientists are working to progress with every potential development.

In the USA, on the manufacturing side, the active ingredients of all vaccines produced by the Protein Sciences Corporation, for example, are recombinant proteins manufactured using its patented protein expression technology that is based on baculovirus and insect cell technology. The firm’s PanBlok, a seasonal recombinant trivalent influenza vaccine, consists of influenza haemagglutin (HA) proteins and is being manufactured for a potential pandemic swine flu. PanBlok is highly purified so does not require the use of thimerosal or antibiotics and is low in endotoxins. The company expects the vaccine to receive FDA approval in time for the 2009/2010 influenza season.

On the academic research front, Richard Compans PhD, Professor of Microbiology and Immunology at Emory University School of Medicine in Atlanta, Georgia, and director of the Emory Influenza Pathogenesis and Immunology Research Center, is studying certain surface glycoproteins expressed by HIV and their ability to elicit immune responses. It is thought that, by assembling virus-like particles bearing these proteins, it may be possible to develop vaccines capable of inducing similar responses, thereby pre-arming the immune system against the virus.

Research avenues

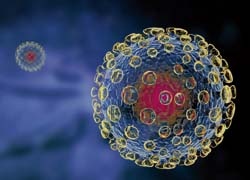

Scientists at the Emory Vaccine Centre have created virus-like particles (VLPs), described as empty shells that look like viruses. They were made by introducing three separate viral genes into baculoviruses, which only infect insect cells. When those baculovirus-infected insect cells are cultured they produce VLPs. Under an electron microscope the VLP structure looks like influenza viruses, but the vital point is they can neither replicate nor cause influenza, explained Holly Korschun, Director of Research Communications for Emory University’s Woodruff Health Sciences Center.

In study results published this March in PLoS ONE**, the Emory team reported that mice immunised by nose drops with the virus-like particles (VLPs) were protected for months against an otherwise lethal H5N1 infection. ‘These results suggest that VLPs could form the basis of an effective human vaccine against H5N1 influenza,’ said Prof Compans.

The H5N1 avian ‘flu variant has killed most of the hundreds of people it is known to have infected. As with the new H1N1 virus, the threat of H5N1 evolving has not diminished – and without a developed immunity among the public, could cause a pandemic.

Prof Compans and lead author Sang-Moo Kang PhD, Assistant Professor of Microbiology and Immunology at Emory, demonstrated the ability of VLPs to stimulate antibody production in mice and, in a collaboration with Ruben Donis PhD and team at the Centers for Disease Control and Prevention, showed that the mice immunised with VLPs could resist a potentially lethal dose of H5N1 virus isolated in Vietnam. The mice’s immunity, including the levels of antibodies that protected their respiratory systems, stayed stable for over six months.

In mice, VLPs appear to deliver several times more potency per microgram than other types of vaccines, such as the chemically inactivated subunit viral vaccine currently in use, or a single viral protein produced in baculovirus. ‘This extra potency is important because the current egg-grown vaccines require relatively high doses to be effective for most people, and in a pandemic demand might run up against production capacity. VLPs could offer more bang for the buck,’ said Prof Compans.

Some next steps in the development of the vaccine are to find out if it can also protect against infection by mutant forms of the virus that arise frequently in birds, he added.

A/H1N1 vaccines in progress

At the end of May this year, to enable vaccine manufacturers to begin the large-scale production of vaccines, they were supplied with the new influenza A/H1N1 seed virus from WHO International Reference Centres.

Among the recipients was the French firm Sanofi Pasteur, which has begun ‘passaging’, a process of sub-culturing cells to produce enough working seed for vaccine production. ‘Passaging is the process for acclimating virus to grow in a production environment at optimum yield. The passaging process is expected to take approximately two weeks. Following quality controls, Sanofi Pasteur will be prepared to begin industrial production as soon as directed by public health agencies,’ the firm announced, adding that it could have the first bulk concentrate vaccine within four to six months. Availability then would be subject to regulatory approval.

Novartis also received reassortant seed from the Centers for Disease Control and Prevention (CDC). In June the firm announced that it had successfully completed the production of the first batch of influenza A/H1N1 vaccine, weeks ahead of expectations due to its cell-based manufacturing technology.

That first 10-litre batch of wild type influenza A/H1N1 vaccine monobulk will be used for pre-clinical evaluation and testing. Based on this rapid success, the firm expects to achieve rapid scale up of influenza A/H1N1 vaccine production with the supplied reassortant seed. Clinical trials of the vaccine are planned to being in July; licensing should follow this autumn.

Already in full-scale production

Baxter International Inc announced in June that it had completed testing and evaluation of the A/H1N1 influenza virus and was in full-scale production of a commercial A/H1N1 vaccine using its Vero cell culture technology — a continuous cell line initially derived in 1962 from African green monkey Chlorocebus kidney epithelial cells — which assures an unlimited supply of cells without having to generate additional animal cells, Baxter explained.

For vaccine production, a frozen vial of seed (starter virus) is thawed and then injected into a large bioreactor. Following growth and reproduction the virus is harvested and inactivated. It is then purified and quality tested before being formulated and filled into vials or syringes. Baxter grows the wild-type virus directly in its Vero cell culture, which reduces production time. ‘Wild-type virus is important because Baxter can work with the virus as it exists in nature, and create a vaccine with a better fit to the virus circulating in nature, as opposed to working with a genetically altered strain of the virus,’ the firm explains.

Having received an A/H1N1 strain from the USA’s Centers for Disease Control and Prevention in early May, Baxter expects to deliver its vaccine for use as early as July,

Using its Vero cell technology, Baxter received European Medicines Agency

(EMEA) approval for a mock-up pandemic vaccine brand-named Celvapan. Because the new influenza A/H1N1 virus strain was used to produce this ‘mock dossier’, the qualification, development and manufacturing processes used in gaining mock-up licensing for Celvapan apply, and that should fast track its approval as a pandemic vaccine. Baxter reports that it will submit the A/H1N1 vaccine for approval after the completion of initial manufacturing runs.

The firm believes that its Vero cell technology can be used to safely and reliably produce a vaccine, and that the technology’s advantages may enable more rapid production and delivery of pandemic

vaccines.

A converse view: In his article titled ‘Swine flu – how proportionate is the response?’ (Pub: Caduseus journal. www.caduseus/info) Dr Robert Verkerk, a former research fellow at Imperial College London and Executive Director of the Alliance for Natural Health, queries its threat and advises a bigger focus on building the human immune system.

* As chronicled in the book ‘Cell culture technology for pharmaceutical and cell-based therapies’, edited by Sadettin S Ozturk and Wei-Shu Hu. Pub: Taylor and Francis Inc).

** Public Library of Science ONE: SM Kang et al. Induction of Long-term Protective Immune Responses by Influenza H5N1 Virus-Like Particles.

01.07.2009