Innovation: UK hand-held device could challenge ELISA’s position

On the cards: Printed circuit board technology for same-day disease diagnosis

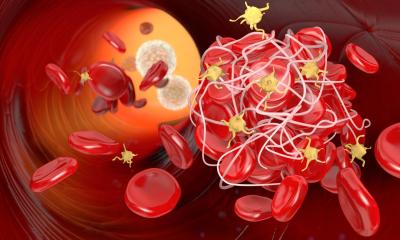

UK scientists are developing a hand-held testing device for use at the point of care and provide a disease diagnosis on the same day.

The device will use disposable cartridges and utilise printed circuit board technology (PCB) to enable a fast low-cost diagnosis.

Initially, the machine will diagnose tuberculosis (TB), but the researchers report that the technology is versatile and later on will be used for other conditions, using DNA from the patient’s blood or saliva samples.

According to the University of Southampton research team, the new device could replace the current conventional diagnostic method of enzyme-linked immunosorbent assay (ELISA), which monitors proteins such as cytokines to identify a disease and measure its progression. However, this is lengthy and limited to single point measurements, due to the prohibitive costs and sample volumes required, preventing continuous monitoring of disease progression.

Leading the research to develop the hybrid technology using electronic components as chemical sensors on PCBs is Dr Themis Prodromakis, a Reader in Nanoelectronics and EPSRC (Engineering and Physical Sciences Research Council) Fellow at the University of Southampton.

The device can carry out diagnosis on the same day and at the point-of-care – potentially avoiding the need to send protein samples to labs for chemical assessment and diagnosis. Consequently, it could lead to health benefits in reducing time to treatment and reducing costs in diagnosis and late-diagnosis treatments.

Dr Prodromakis explained: ‘A project of this nature is the perfect illustration of how academia, manufacturing and the end user can come together to pool knowledge and experience to make a real and valuable change. There’s a real opportunity for this new diagnostic tool to make a tangible difference to healthcare in international markets.’

Although at a preliminary stage, it is hoped that the test will become available in hospitals, GP surgeries or even for diagnoses in the home.

In the three-year project researchers in the Department of Infection and Immunity at Imperial College Healthcare NHS will carry out all clinical trials, and collaborate with Newbury Electronics, a British PCBS manufacturer of PCBs, which contributes extensive knowledge of manufacturing techniques and materials to the work.

Philip King, a director at Newbury Electronics, said Dr Prodromakis and team have come up with an ‘exciting’ alternative to more traditional diagnostic methods. ‘It’s now our job, as the expert manufacturers, to help transform this idea into a feasible product,’ he said. ‘The inclusion of Imperial College as the clinicians to demonstrate the relevance of this research ensures that valid input from all sides is incorporated right from the initial stages.’

The research is funded by £1m (€800,000) awarded by the EPSRC. Presently, Prodromakis and team are working with Newbury Electronics to gain a better understanding of the printed circuit board manufacturing process and how to refine and amend this to use alternative materials and to finer degrees of accuracy.

The team’s aim is for the first prototypes to be available for initial testing by 2015.

Profile:

Dr Themis Prodromakis is a Reader in Nanoelectronics and EPSRC Fellow affiliated with the Nano Research Group and the Southampton Nanofabrication Centre of ECS at University of Southampton. He is also an Honorary Research Fellow at Imperial College London. Previously he held a Corrigan Fellowship in Nanoscale Technology and Science, funded by the Corrigan Foundation and LSI Inc., within the Centre for Bio-inspired Technology at Imperial College and a Lindemann Trust Visiting Fellowship in EECS UC Berkeley. His background is in Electron Devices and micro/nano-electronics processing techniques, with research on bio-inspired devices for biomedical applications.

20.08.2014