Automation

Faster liquid handling system development for OEM applications

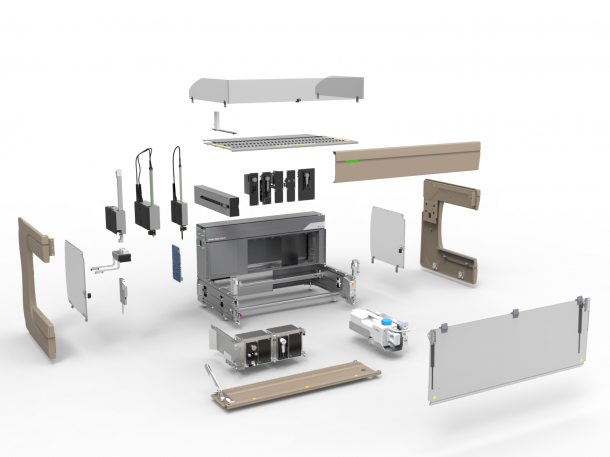

Tecan is making it quicker and easier than ever before for manufacturers to develop instruments for advanced liquid handling applications. The launch of the new Cavro Omni Flex further extends the flexibility and convenience of the company’s popular Cavro Omni Robot by offering more hardware options to complement its precision pipetting, including frames, worktables, power and input/output management, racks and all the pumps and other options required to perform liquid handling tasks.

Tecan understands that rapid development and testing are crucial to achieve the shortest possible time-to-market, and has designed the Cavro Omni Flex to simplify prototyping, method development and regulatory approval. This highly modular system allows virtually any combination of axes, pipetting modules, pumps and worktable options, with a wide range of additional options – such as skins, shields, sensors, locks and carriers – to suit the needs of individual instrument designs and applications. Using UL-recognized components and developed with RoHS and FDA criteria in mind, the Cavro Omni Flex is designed to streamline and simplify regulatory approval for laboratory and diagnostic instrumentation. Backed by over 40 years of Tecan Cavro liquid handling know-how in OEM and IVD markets, this ensures complete peace of mind and reliable, trouble-free operation to exactly match your application needs.

To find out more about Tecan’s Cavro Omni Flex, visit www.tecan.com/omniflex

Source: Tecan

05.12.2016