Image source: Dickson

News • Environmental monitoring

New generation of smart sensors introduced

Manual calibration and parameter input in systems are time-intensive and error-prone, posing significant challenges across life sciences and hospitals.

Studies reveal that manual data entry carries a 4% error rate, equating to as many as 400 errors in 10,000 entries. Additionally, employees can spend over 100 hours monthly on tasks like calibration parameters manual entry, consuming valuable resources. These inefficiencies not only hinder productivity but expose processes to human error. Automation and smart sensor technology offer a transformative solution, streamlining workflows, minimizing errors, and reclaiming countless hours, enabling businesses to operate with enhanced precision and efficiency.

Ten years ago, The Dickson Company pioneered smart sensing with the launch of the patented "Replaceable Sensors". Now, the company is launching Smart DS, its second generation of intelligent sensors. This in-house solution is built on years of field experience and customer feedback, delivering a smarter, easier to use, and more autonomous monitoring solution. By embedding calibration and traceability data directly into each sensor, Smart DS eliminates the need for full device recalibration, the manufacturer states.

Image source: Dickson

This new architecture is designed for faster sensor replacement, uninterrupted monitoring, and total compliance across all applications where precision and reliability are non-negotiable. Designed for critical environments like freezers, refrigerators, cleanrooms, laboratories or pharmaceutical storage, this second generation of smart sensors ensures continuous tracking of ambient conditions, from temperature to humidity, differential pressure and CO2.

The product launch means every Dickson sensor is now built with next-generation smart technology, for use in an array of applications. According to the company, the technology enables seamless maintenance, reduces downtime, and ensures full traceability of calibration data. “Thanks to a decade of experience in smart sensing, we are introducing a new product even more suited to the needs of highly regulated industries to gain access to a high-performance monitoring solution built to perform in critical conditions,” they state.

As a result, the new sensors can now support all critical applications seamlessly:

- Digital temperature sensors

- Digital temperature and humidity sensors

- 3-in-1 digital sensors for CO2, temperature, and humidity

- Digital differential pressure sensors

- 4-20 mA compatible smart sensors

- Smart PT100 temperature sensors

“Smart Sensors from Dickson combine precision, compliance and ease of use into a single powerful solution. This innovative technology reflects our continued commitment to delivering advanced monitoring systems that reduce complexity, enhance efficiency and help customers meet the highest regulatory standards within critical environments,” says Rick Weiler, Dickson CEO and President.

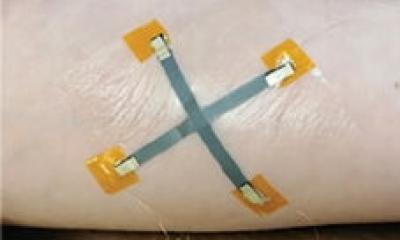

The new Smart DS temperature probe completes the company's solution line-up designed for use in critical environments. Designed with their second-generation smart sensor technology, it enables a powerful and user-friendly monitoring experience for highly regulated industries.

Features:

- Flat cable for better equipment integration

- Temperature range: -40°F to +176°F

- Complete integration with DicksonOne and OCEAView ecosystems

- All the advantages of Smart Sensor Technology

Source: The Dickson Company

17.07.2025