Image source: Chulangkorn University

News • Resource management

Automated filling machine could stave off Covid-19 vaccine shortage

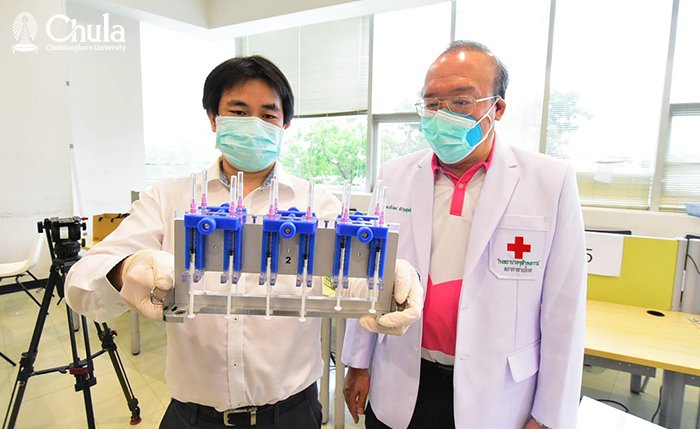

Researchers in Thailand have developed a device to get the most out of vaccine supplies: The automated vaccine filling machine from the Faculty of Engineering at Chulalongkorn University (Chula) can fill AstraZeneca vaccine into syringes with precision, speed, and safety, helping to increase the number of vaccinated people by 20 percent.

The prototype is now operating at Chula Vaccination Center and more machines are planned to be built to support frontline medical personnel in many vaccination centers soon.

Mass vaccination for a large population can pose as a major problem that requires immediate attention to contain the spread of Covid-19 as soon as possible. However, there are limitations. AstraZeneca vaccine comes in multi-dose vials that have to be drawn into syringes in equal amounts. The medical personnel is overwhelmed with the daunting task of vaccinating a large number of people each day. These are the problems that the Faculty of Engineering tried to address with the development of an automated vaccine filling machine that ensures the precision of the draw, thereby increasing the number of vaccinated recipients by 20 percent, as well as relieving the burden of medical personnel.

Image source: Chulangkorn University

The machine [...] accurately extracts 12 doses of vaccine from a vial, thus increasing the number of vaccinated people to 12 per each vial, and ensuring the accuracy of vaccine volume in every injection

Juthamas Ratanavaraporn

The Thai Ministry of Public Health has chosen “AstraZeneca” as the country’s main vaccine and plans to administer 61 million doses to the Thai people by medical personnel. AstraZeneca vaccine comes in 10-dose vials, but the manufacturers fill the vials with 13 doses to allow for human impreciseness while drawing the vaccine. This surplus amount is an opportunity to vaccinate more people. Therefore, the Ministry trained Bumrasnaradoon Hospital personnel to draw more than 10 doses, and sometimes they got 11-12 doses, but not consistently. “At Chula Engineering, we are always innovating, and see that automation can do the work for humans in this area. So, we invented the machine that accurately extracts 12 doses of vaccine from a vial, thus increasing the number of vaccinated people to 12 per each vial, and ensuring the accuracy of vaccine volume in every injection,” said Asst. Prof. Dr. Juthamas Ratanavaraporn, Chairperson of the Biomedical Engineering Program, and co-developer of the automated vaccine filling machine with Lecturer Saran Keeratihatayakorn, Office of International Engineering Program Administration, Faculty of Engineering. “Currently, vaccines are limited. The fact that we can increase vaccination by 20 percent is extremely beneficial to the country,” Asst. Prof. Dr. Juthamas emphasized.

Image source: Chulangkorn University

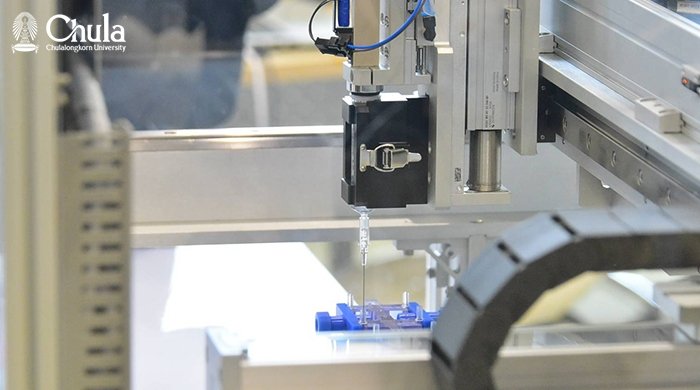

The Faculty of Engineering, Chulalongkorn University, in collaboration with the Department of Medical Sciences, Ministry of Health and various companies from the private sector developed the machine to be safe and free from contamination at maximum efficiency. Most importantly, it can easily be operated by only one non-medical operator. “Staff will place 12 syringes on a platform, and a vial of the vaccine on the designated spot on the conveyer belt. A vacuum nozzle will drain all the 6.5 ml. of vaccine from the vial into each of the 10-ml syringes with an air-cushion suction method, so the vaccine will not come in direct contact with the suction nozzle and there is no worry about contamination. The syringes and needles are replaced with new ones every time, so it is safe with no contamination,” added Asst. Prof. Dr. Juthamas.

“The conveyor belt allows the vaccine to be filled into syringes continuously and quickly. It takes about 4 minutes to fill, then the syringes are capped with injection needles, and placed on vaccine trays, ready for immediate injection. This greatly relieves the burden of the frontline medical personnel, reduces the time required for this step, and increases the vaccination by 20 percent or 1,700 additional doses per day.”

Asst. Prof. Dr. Juthamas said that this concept can be applied to other alternative vaccines that are packaged in multiple doses as well. At present, the prototype is already being piloted at the Chula Vaccination Center. Asst. Prof. Dr. Juthamas revealed that a plan is underway to produce another 100 units to distribute to large vaccination centers that give more than 1,000 doses of vaccination per day, such as the Bang Sue Central Station or provincial hospitals. In addition, talks about exporting the device to neighboring countries that use similar vaccines are in the works, and details are being worked out with the Ministry of Public Health. Moreover, the automated vaccine filling machine can also be adapted to work with other mRNA vaccines such as the Pfizer vaccine. The researchers are working on using the same concept with some adjustments.

Source: Chulangkorn University

07.09.2021