News • Sticky, yet promising research

3D printing lung tissue from mucus-based bioink

Lung diseases kill millions of people around the world each year. Treatment options are limited, and animal models for studying these illnesses and experimental medications are inadequate.

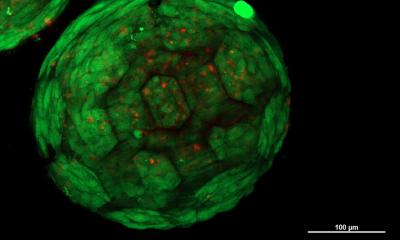

Image source: American Chemical Society; from: Sasikumar SC, Goswami U, Raichur AM; ACS Applied Bio Materials 2024

Now, researchers describe in ACS Applied Bio Materials their success in creating a mucus-based bioink for 3D printing lung tissue. This advance could one day help study and treat chronic lung conditions.

While some people with lung diseases receive transplants, donor organs remain in short supply. As an alternative, medications and other treatments can be used to manage symptoms, but no cure is available for disorders such as chronic obstructive pulmonary disease and cystic fibrosis. Researchers continue to seek better medications, often relying on testing in rodents. But these animal models may only partially capture the complexities of pulmonary diseases in humans, and they might not accurately predict the safety and efficacy of new drugs. Meanwhile, bioengineers are exploring the production of lung tissue in the lab, either as a more accurate model to study human lungs or as a potential material to use in implants. One technique involves 3D printing structures that mimic human tissue, but designing a suitable bioink to support cell growth remains challenging. So, Professor Ashok Raichur, from the Department of Materials Engineering at the Indian Institute of Science Bangalore, and colleagues set out to overcome this obstacle.

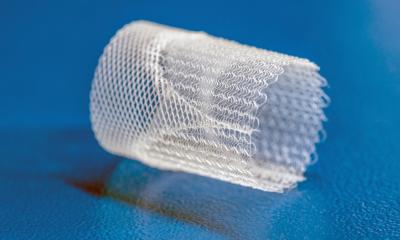

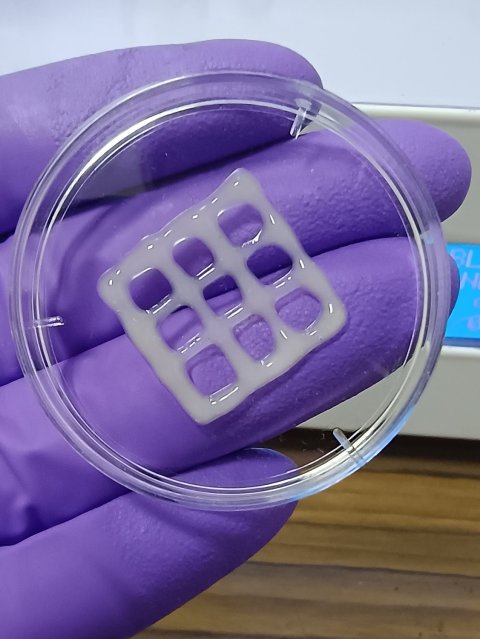

The team began with mucin, a mucus component that hasn’t been widely explored for bioprinting. Segments of this antibacterial polymer’s molecular structure resemble epidermal growth factor, a protein that promotes cell attachment and growth. Raichur and colleagues reacted mucin with methacrylic anhydride to form methacrylated mucin (MuMA), which they then mixed with lung cells. Hyaluronic acid — a natural polymer found in connective and other tissues — was added to increase the bioink’s viscosity and enhance cell growth and adhesion to MuMA. After the ink was printed in test patterns including round and square grids, it was exposed to blue light to crosslink the MuMA molecules. The crosslink bonds stabilized the printed structure in the form of a porous gel that readily absorbed water to support cell survival.

The researchers found that the interconnected pores in the gel facilitated diffusion of nutrients and oxygen, encouraging cell growth and formation of lung tissue. The printed structures were nontoxic and slowly biodegraded under physiological conditions, making them potentially suitable as implants in which the printed scaffold would gradually be replaced by newly grown lung tissue. The bioink could also be used to make 3D models of lungs to study lung disease processes and evaluate potential treatments.

Source: American Chemical Society

02.08.2024