Screenshot "Video report project meeting"

Article • Orthopaedics

VR training to improve hip replacement surgery

More than 200,000 patients undergo hip replacement surgery in Germany each year. To avoid complications and extend the lifespan of the artificial joint, the implants must be fitted precisely in the acetabulum (hip socket). The procedure, particularly milling the acetabulum, is not only difficult but also the technique is difficult to teach and train.

Report: Sascha Keutel

This is where HIPS (HüftImplantatPfannenfräsSimulator) – a hip replacement socket milling simulator – comes in. Developed by a research consortium, ‘HIPS is the worldwide first virtual reality (VR) training simulator for hip replacement surgery that provides haptic feedback and can simulate interventions that need high and stable forces,’ explains Mario Lorenz, from the Technical University of Chemnitz, who initiated this project.

© HIPS project

The prime goal of the researchers was to improve specialist physician training, as Lorenz underlines: ‘Today, specialist physicians in training practice on phantoms, i.e. artificial bones. Material behaviour, however, does not mirror the behaviour of actual bones closely enough which, in fact, also holds true for donor bone material – a rare and extremely valuable resource in medical training and research.’

Specialist physicians in training have to assist in a number of surgical operations before being asked to perform the milling step themselves. ‘Wouldn’t it be much better if physicians in training had performed several simulations that are as close as possible to the real thing before that crucial moment arrives? Wouldn’t it be better to give them an opportunity to develop the necessary feel for the procedure, build self-confidence and allow them to make errors from which they can learn?’ Lorenz asks. In minimally invasive surgery, such as keyhole interventions, VR training has been around for about 20 years, Lorenz points out, adding, ‘For procedures that need high forces, such simulation products are not available, neither commercially nor for research purposes.’

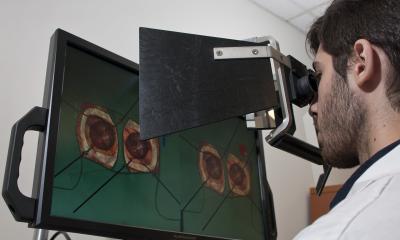

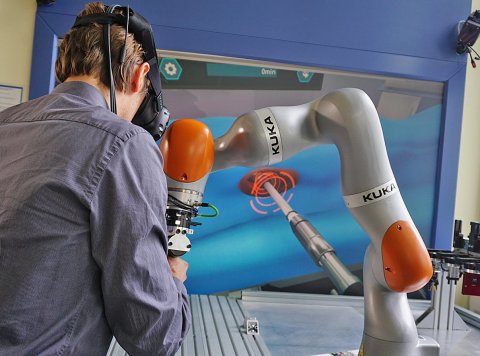

HIPS users see the virtual patient’s hips through VR glasses, while they operate a surgical milling instrument which is connected to a lightweight robot, the BR iiwa. The user has to mill the hip joint’s acetabulum – something that is difficult to teach, train and learn. The robot delivers direct haptic feedback by simulating the resistance of a real bone. Thus, the user acquires a better feel for the forces at work and the area that can be worked.

The simulation is based on real data. To compute the forces and torques when milling the hip, the researchers conducted biomechanical tests with anatomical specimens. ‘We found out that we are dealing with up to 200 Newton. Force is needed when the surgeon applies pressure on the acetabulum. The forces applied on the surgeon’s wrists when the machine stops is between 20 and 50 Newton depending on the size of the wrist,’ Lorenz explains. With these measurement data, researchers at the University of Bremen, Germany, designed a material model that allows a surgeon to compute, within a millisecond, where the surgical milling instrument meets the acetabulum and what forces are present.

In a next step, a software module was developed that features a user interface integrated by FAKT Software GmbH. The result is an interactive application based on an anatomical model by CAT Production GmbH, which had created the anatomical 3-D models and the virtual operating room (OR). The team at the Technical University Chemnitz developed the interface with the robot arm to ‘tell’ the robot the force it has to simulate. ‘Originally, the robot was certified for collaborative human-machine tasks on the shop floor. We managed to use the existing interface to provide the user with haptic feedback while maintaining the certification,’ Lorenz points out.

© TU Chemnitz/Rene Apitzsch

The three-year HIPS project received €670,000 from the German Federal Ministry of Economics and Energy (BMWi). The project consortium consisted of the Chair of Machine Tools at the Technical University Chemnitz, the Institute of Computer Graphics and Virtual Reality at the University of Bremen, Leipzig-based FAKT Software GmbH in Leipzig and CAT Production GmbH in Munich.

The medical development partner was the Clinic for Orthopaedics, Trauma und Plastic Surgery at University Hospital Leipzig, ZESBO (Centre for Research on the Musculoskeletal System), the research team Clinical Anatomy at the University of Otago, New Zealand, and the Department of Medical Technology at Fraunhofer Institute for Machine Tools and Forming Technology.

Profile:

After having completed his informatics program in 2010, at Westsächsische Hochschule Zwickau, Germany, Mario Lorenz was appointed assistant at the Chair of Machine Tools at the Technical University Chemnitz in the field of VR and Augmented Reality (AR). In 2016, he also became a guest scientist at the Clinic for Orthopaedics, Trauma and Plastic Surgery at University Hospital Leipzig. His research focuses on the use of VR and AR technologies in production and medical training.

07.04.2020