Students learn to create tissue

In September 2015, Utrecht University and University Medical Center (UMC) Utrecht will begin offering a two-year Biofabrication research master’s program in partnership with three foreign universities.

The program is the first in the world in which students will study the technology involved in creating tissue, including 3D bioprinting. Students will spend one year at a partner university and will have the opportunity to obtain a double degree.

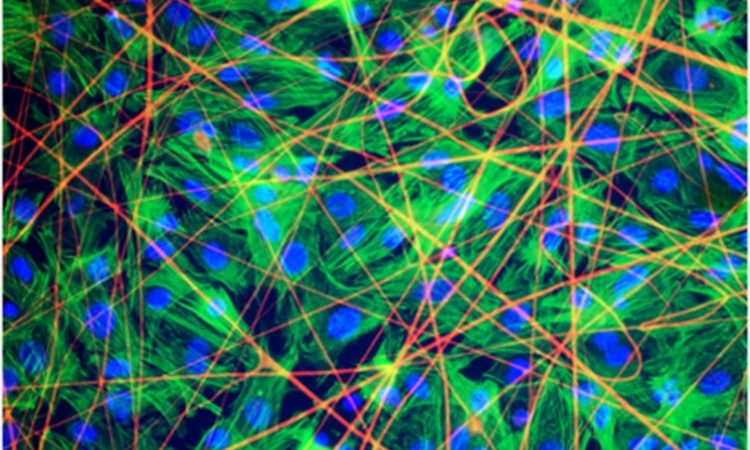

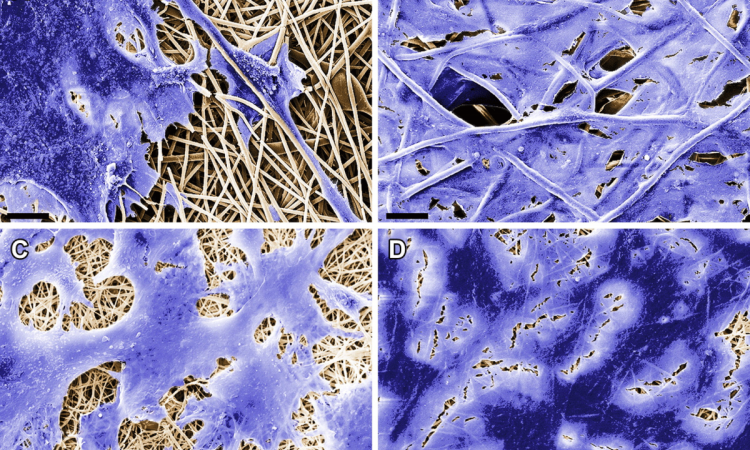

The human body is not capable of replacing complete organs. However, thanks to the emerging regenerative medicine, we can help the body to repair organs and replace lost tissue. Biofabrication combines advanced fabrication technology (like 3D printing) with biological systems to create engineered tissue constructs. These can be used in regenerative medicine research as well as for therapy and medicinal products. The expected increase in the demand for highly qualified biomedical engineers in this field prompted Utrecht University to introduce the master in Biofabrication.

Multidisciplinary

In the program, students will learn to develop methods for creating tissue. Biofabrication is a multidisciplinary field of research which requires a knowledge of chemistry, physics, biology, medicine, robotics and computer science. “It’s great that graduates will now have the opportunity to acquire these skills and knowledge, and gain international experience in this two-year program,” says program leader dr. Jos Malda. “They will be able to use the competencies they acquire to shape the biofabrication and 3D-printing industries.”

International

The master’s program will be offered by Utrecht University/UMC Utrecht and the University of Wurzburg (Germany) in Europe in partnership with Queensland University of Technology in Brisbane and the University of Wollongong in Australia. Dutch students will follow the first year of the program in Utrecht. In the second year, they will perform a research study and follow additional courses at one of the Australian universities. To facilitate this, ten outstanding students will be awarded an EU grant. “This grant will enable students to perform research in Australia by providing funds for travel and accommodation expenses,” explains program coordinator dr. Ferry Melchels. “The participating parties are among the world’s leaders in this new and exciting field of research. The EU grant is proof that this level of excellence is recognised.”

Experimental tissue factory

Among other things, the students will have access to the Utrecht Biofabrication Facility, an experimental tissue factory at the Utrecht Science Park that was established early this year. The 3D bioprinters set up in this high-tech facility are able to print tissue structures, layer by layer.

Life Sciences

The Master’s in Biofabrication is in perfect alignment with the University of Utrecht’s strategic research theme of Life Sciences. It falls under the subtheme Regenerative Medicine & Stem Cells, which focuses on repairing and replacing tissue. Within Utrecht Life Sciences, Utrecht University works in close collaboration with the UMC Utrecht, Utrecht University of Applied Sciences, the Hubrecht Institute and the Danone Research Centre for Specialised Nutrition. Other partners in Utrecht and beyond include the Netherlands Organisation for Applied Scientific Research (TNO), the National Institute for Public Health and the Environment (RIVM), Eindhoven University of Technology and various international institutions.

Press release: UMC Utrecht

08.10.2014