Image credit: Rabin Medical Centre / Belinson

Article • Creating instruments, implants & more onsite

Reforming surgical procedures with 3D printing hubs in hospitals

Increasingly, hospitals use 3-D printing in surgery because the technology can enable fast, unique production of patient-tailored tools at relatively low costs.

Report: Sascha Keutel

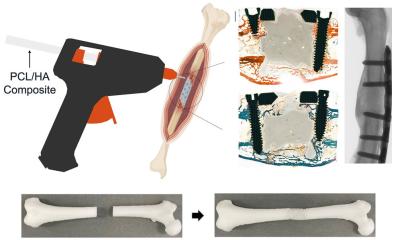

‘As the technology itself is developing and accelerating at a fast pace, hospitals may be left behind if they choose not to adopt these advances,’ said Limor Haviv, surgical 3D printing designer at 3D4OP. Today, 3D printing is used in various medical fields, and implemented in four primary surgical applications: pre-surgical planning, customised surgical models, patient-specific instruments, and customised implants.

Most surgeons outsourced the use of 3D printing technology. They sent DICOM data to a dedicated company that executes segmentation, print models, cutting guides or patient specific instruments. In these cases, surgeons would receive 3D products, but they could not test and simulate their use. As such, hospital implementation requires a different scope and different vision. With a hub in the hospital, surgeons could be involved in all steps of the process, from segmentation, through to planning until the actual surgery. ‘An in-house 3D printing hub, with an in-house specialist designer such as myself allows surgeons to experience the entire process,’ Haviv pointed out.

Benefits

There is something for everyone – each surgical discipline can benefit from different aspects of this broad technology

Limor Haviv

In the hubs, surgeons are encouraged to participate in all stages of the work process, from processing MRI and CT scans into 3D images to brainstorming issues and finding the precise tools and implants needed for each operation.

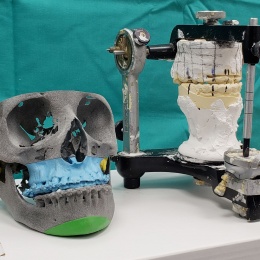

Digital models help surgeons to plan positioning of tools and implants. Printed models allow the simulation of a dry run before surgery and also to assist in achieving better results through more accurate complex geographic resections in proximity to joints and better adjustment to the patient’s body. Being able to see a 3D model or a 3D-PDF image on screen brings different views and opens up discussion to new surgical approaches, improving decision making processes in multidisciplinary meetings.

They also provide exact surgical tools that improve procedure outcome. ‘3D printing hubs can include segmentation software, sophisticated CAD software, 3D printers, virtual reality stations for practicing and more. There is something for everyone – each surgical discipline can benefit from different aspects of this broad technology.’

How to build a hub

According to Haviv, medical centres planning to establish a 3D printing hub should concentrate on the first steps of the process, imaging and planning, using dedicated software. ‘These are crucial steps for better surgical planning. Technical issues, such as materials and printing, can still be left to the dedicated companies at this stage,’ Haviv explained. In the second stage, hospital labs should purchase an easy-to-use desktop 3D printer for printing basic anatomical models or jigs.

The transition from 3D lab to manufacturing plant for complex models, tools, jigs or implants is a bigger leap and, in Haviv’s opinion, unnecessary. Instead, 3D labs in hospitals should focus on the initial design stages and leave the manufacturing and complex printing to external companies. These stages need expensive machinery and include post processing, packaging, labelling, sterilisation and, of course, adherence to legislation, medical regulations and ISO certification.

Conclusion

Surgical 3D printing hubs give surgeons from all disciplines 3D tools to improve their surgical understanding and technique through improved visualisation and the opportunity to plan ahead. A 3D hub in a hospital should be the link between the technology, the medical data and the printing companies. Even if printing is still outsourced, much of the process can be carried out in-house. ‘In my experience, surgeons who experience the benefits of 3D printing technology and the designs that I help them bring to life, not only trust the technology more but also understand all the immense benefits it has to offer,’ Haviv summarised.

Profile:

In 2015, Limor Haviv gained her Bachelor of Design (B.des) in Inclusive Industrial Design and up to 2018, directed Synergy3DMed and 3D Printing Surgical Lab at Tel-Aviv Medical Centre. In 2018, she established her own company – 3D4OP. As a Surgical 3D Printing Designer Haviv assists surgeons in pre-surgical planning processes, from segmentation through to simulated surgical planning to 3D printing. She has already been part of more than 350 surgical procedures.

05.11.2020