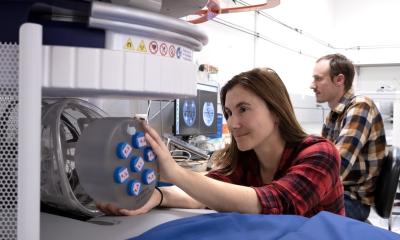

Photo: M. Rouger

Article • Low-field imaging from Shanghai: engineering portable precision

Moving MRI closer to the patient – one hand-pushed scanner at a time

Can a full MRI scanner be shrunk to fit through a hospital door, moved by hand, and still produce diagnostic images – including 3D and DWI sequences? At the ESMRMB 2025 Congress in Marseille, Zhiyong Zhang, researcher at Shanghai Jiao Tong University, offered a detailed demonstration that the answer is yes – if you re-engineer every layer of the machine, from magnets to mobility.

By Mélisande Rouger

‘Low-field MRI is not just a scaled-down version of high-field,’ he said. ‘It requires its own architecture, its own sequences, its own way of thinking.’

From heavy to hand-pulled

Zhang’s team began by building a 0.25T scanner, but the machine weighed two tons. ‘That was too heavy for mobility,’ he explained. So they redesigned a 0.21T version, integrating all RF and gradient electronics into a compact structure that fits into a portable housing. ‘Now, one person can move it. I can move it myself.’

The system has since been deployed in teaching hospitals, with five full units now operating in Zhang’s lab. ‘We wanted something small, reproducible, and locally operable,’ he said. The structure also allows it to be mounted on a truck for mobile imaging – another step toward decentralised MRI access.

Image quality at low field: engineering, not magic

‘We show T1, T2, FLAIR, and 3D T2 images – all acquired on our system,’ Zhang said. ‘And none of it is AI-enhanced. This is raw imaging.’ But achieving those images required more than hardware. ‘Low field means low SNR,’ he said. ‘And that means every imperfection matters.’ Zhang broke down the system’s design into three core challenges: hardware interference, sequence optimisation, and image correction.

1. Electromagnetic noise

Many open-source or DIY MRI setups struggle with EMC (electromagnetic compatibility). Zhang’s team analysed the normal frequency ranges of all commercial components – from power supplies to amplifiers – and built custom shielding and filters to isolate noise. ‘If your switching amplifier has harmonics close to your imaging bandwidth,’ he warned, ‘you’ll see artifacts – or no image at all.’

2. Gradient instability

To eliminate ghosting and geometric distortions, Zhang designed a real-time correction method using field probes that measure gradient fields directly in x, y, and z axes. ‘Image-based corrections take hours or days,’ he said. ‘With field probes, we can do it in a few minutes, and compensate for high-order eddy currents in real time.’ They also mapped and corrected for concomitant fields using Maxwell-based models – essential for clean DWI acquisitions at low field.

3. Temperature sensitivity

‘Low-field systems are much more sensitive to temperature drift,’ Zhang noted. To stabilise the central frequency, his team implemented monitoring and feedback systems throughout the scan process.

Sequence innovation for low field

Zhang’s talk highlighted how sequence engineering must be rethought entirely for low-field environments. The team developed multi-band FSE and EPI sequences – typically used in high-field applications – and adapted them for their lower-power system.

‘In high field, multiband FSE is limited by SAR,’ he said. ‘At low field, you need less than 1kW to drive it – versus 16kW in high-field systems.’ Using quadratic phase increments, they improved echo stability and suppressed signal oscillations, enabling longer acquisition windows. Combined with RF encoding techniques, this led to clearer contrasts and faster imaging – including full head scans in under 10 minutes.

DWI at low field: the final frontier

‘Diffusion imaging is the hardest to achieve,’ Zhang admitted. ‘All open-source systems struggle with DWI.’ But after successive rounds of hardware filtering and sequence optimisation, his team succeeded in acquiring trace-weighted DWI images with their EPI-based sequence. ‘We’re not at the same resolution as 3T systems,’ he said. ‘But the clinical utility is there – and we’re improving every month.’

Design matters: MRI for humans, not just engineers

The team also partnered with industrial design students to adapt the machine to real-world environments. The latest scanner model is less than 80 cm wide, making it small enough to fit in elevators or through hospital doors – a critical threshold in many facilities. ‘We added force sensors and touch-based movement,’ Zhang said. ‘You push it, it moves; you pull, it follows.’

For paediatric imaging, the design is even more intentional: rounded shapes, colourful surfaces, embedded screens, and accessories to hold iPads or toys during scans. ‘The goal is to create a space where children feel safe,’ he said. ‘Where parents can stay, and technicians can interact.’

A growing team, a broader vision

Zhang concluded by crediting his team – including several students who received awards for their work on multiband FSE, hardware filtering, and sequence development. ‘Our work is collaborative, iterative, and grounded in engineering,’ he said. ‘And it’s driven by a clear question: how do we bring MRI closer to people, not just in power, but in practice?’

The answer, shown slide by slide in Marseille, is being built – one filtered amplifier, rephased sequence, and hand-pushed scanner at a time.

20.01.2026