Article • Eco-friendly power source

‘Greener’ mini-batteries to power medical devices

More than 15 billion batteries are sent to landfill sites every year – technology that converts glucose and oxygen into electricity has the potential to reduce this waste and serve as a sustainable alternative power source for medical devices such as pacemakers, glucose monitors and pregnancy kits.

Report: Mark Nicholls

Image source: BeFC

Visitors at the recent Medica/Compamed conference were introduced to the innovative approach and its possibilities by French-based company BeFC at the “Powering the future – Energy generation with papers and enzymes” session. Dr Jules Hammond, CEO of BeFC, described the technology as part of a new wave of smart and connected devices for patient monitoring, glucose monitoring, fertility testing and connected packaging. With an estimate of 50 billion connected units in 2020, this is expected to be a growing market within the industry.

Many of these devices can operate with low power consumption. Dr Hammond proposed that sustainable and clean energy alternatives can be used to power these machines, replacing conventional miniature batteries that often contain toxic materials. The eco-friendly paper-based fuel cells are ultra-thin, lightweight and flexible. Energy is generated via enzymatic reactions and stored using glucose and oxygen, avoiding the use of toxic materials and environmental pollution long after the batteries have been discarded.

Recharging through resources in the bloodstream

Image source: BeFC

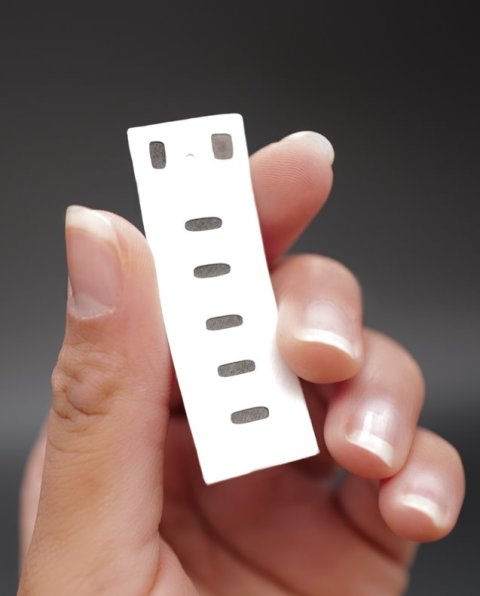

The sustainable power cells developed by BeFC are flexible, lightweight and appropriate for wearable and implantable devices, the company’s CEO pointed out. ‘We use enzymes to convert glucose and oxygen into electricity, very much a bioinspired solution.’ The glucose and oxygen can be harvested from the bloodstream and power items such as pacemakers and insulin pumps, with the biofuel cells being activated by biological fluids such as blood, sweat, or urine. Dr Hammond also presented a "blister reservoir" as an alternative mode of activation, with the technology able to last for days or even months, depending on use case. The power source can also be sterilised with no obvious signs of degradation, he pointed out.

The fuel cells are constructed as a stack of cellulose and carbon layers. Its function is based on the use of different enzymes immobilised on the electrodes. One enzyme is used to oxidise glucose, liberating electrons, which are harvested through the electrode. A different enzyme then reduces oxygen into water, which pulls electrons through the electrical circuit with the combination of the two half-cell reactions creating the biofuel cell.

Reliable even when the lights go out

Image source: BeFC

The shape and size of the paper biofuel cell can be adjusted or enlarged as necessary. Current models are 600 microns in thickness, with plans to reduce to 250 microns in 2022. Dr Hammond reported that his company is working with partners to scale up their production from a robotic sheet-to-sheet process to a roll-to-roll process.

A major obstacle that prevents many green and flexible energy sources from use in wearables is their tendency to produce only unreliable power output. As an example, photovoltaics require exposure to direct light to achieve useful power densities – this makes the technology unsuitable for devices worn underneath garments. Due to their structure, the batteries developed by BeFC are not limited in this way, the CEO pointed out.

He expressed confidence in the technology developed by his team of engineers, scientists and problem-solvers, with academic backgrounds in biosensors, printed batteries and paper microfluids. ‘What we are looking to do is provide smart and connected devices that represent the minimal environmental amount of impact.’ Dr Hammond expressed his belief that medical application will become a major market for these low-cost, green platforms, which will combine metal-free and plastic-free energy solutions with printed electronics.

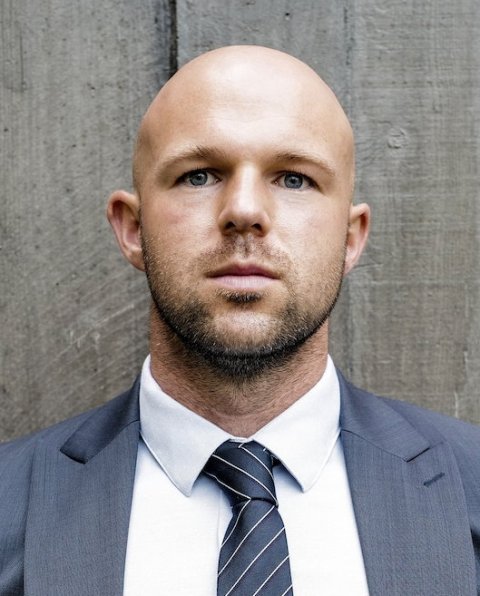

Profile:

Dr Jules Hammond is CEO and cofounder of BeFC. Having completed his BEng and MEng degrees in electronic engineering, he continued his studies, completing a PhD in nanofabricated biosensors at the University of Bath in the UK and then joined the group of Dr Serge Cosnier at Grenoble to develop novel biofuel cells. As a CEO, Dr Hammond is focused on hiring talent to build an interdisciplinary team of problem-solvers. He develops the strategy to guide the company towards its mission of replacing conventional miniature batteries with eco-friendly technology, to provide a sustainable energy solution for low-power electronics.

17.03.2022