Faster Throughput

Automation and the Future of Microbiology Laboratories

When it comes to automation, clinical microbiology has for many years lagged behind other laboratory disciplines. Robotics and computer processing revolutionized chemistry and hematology instruments decades ago. Meanwhile, clinical microbiologists continue to open specimen containers by hand and grow bacteria using methods familiar to microbiology’s founding fathers from the 19th century.

Early attempts at microbiology automation were foiled not only by the variety of specimens and container types—from stool samples and bone biopsies to tubes of blood—but also by the variety in methods required to identify organisms. Even as mass spectrometry has standardized microbe identification, and blood culture and antimicrobial susceptibility testing have been automated, laboratories still often conduct specimen processing and culture workup by hand. Now, however, that may finally be changing.

Total laboratory automation systems currently are available to handle specimens, streak plates, incubate, and digitally image cultures. “That’s one of the great things about microbiology at the moment,” said Michael Jacobs, MD, PhD, medical director of the microbiology laboratory in the department of pathology at University Hospitals Cleveland Medical Center and professor of pathology at the Case Western Reserve University School of Medicine. “There’s been more change and more advances in the last few years than there have been for decades.”

Debate Over Automation Choices

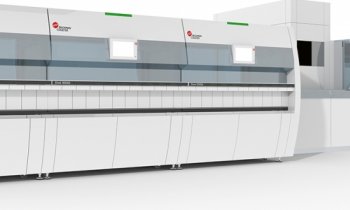

Two microbiology total laboratory automation systems are now available in the United States, BD Kiestra TLA and COPAN Diagnostics WASPLab. While these systems can reduce labor costs and improve turnaround time, some lab directors are still skeptical.

“They automated the wrong century,” commented Steven D. Dallas, PhD, D(ABMM), section chief of the microbiology laboratory at University Hospital in San Antonio. For all the robotics and moving parts, he said, the systems are built around classic techniques—growing colonies on 100 mm agar plates—rather than something truly revolutionary, such as growing microbes on film or using imaging to detect growth of cells rather than colonies. “I’m not totally against the systems,” Dallas said. “It’s just for what they do, they are so amazingly expensive.” Dallas is also an associate professor at the University of Texas Health Science Center at San Antonio.

Advocates for the automated systems say that bigger technological breakthroughs are coming. Nathan A. Ledeboer, PhD, D(ABMM), associate professor of pathology and medical director of clinical microbiology and molecular diagnostics at the Medical College of Wisconsin in Milwaukee, said he and others are working to teach the automation system software to interpret plates. In one study, Ledeboer and colleagues showed that WASPLab software could read chromogenic plates to detect methicillin-resistant Staphylococcus aureus with 100% sensitivity over more than 57,000 samples, in many cases detecting positives that technologists missed (J Clin Microbiol 2016;54:620–4).

In another study, in press, Ledeboer and his colleagues demonstrate how they taught WASPLab to count colonies from urine samples, and they are now training it to distinguish different colony types on blood plates. “We’re still learning,” Ledeboer said. “The full book has not been written on automation. I think there are a lot of questions yet to be answered and there are a lot of opportunities.”

Laboratories already have discovered some surprising benefits of automation. Richard Thomson, PhD, D(ABMM), division head of clinical pathology at NorthShore University HealthSystem in Evanston, Illinois, and clinical professor in pathology at the University of Chicago Pritzker School of Medicine, automated his microbiology laboratory in December 2014. The laboratory, which serves a four-hospital system with almost 900 beds and performs about 300,000 billable tests annually, was the first in the United States to implement BD Kiestra TLA.

Automation enabled a staff reduction of 20%, or six jobs, bringing the staff from 27 to 21 full-time equivalents, Thomson said. He had projected that it would lead to a return on investment in 5 years. Surprisingly, savings from faster results reporting shortened the return on investment to 3 years. “From a financial standpoint it’s been very encouraging to the administrators,” he said.

Some technologists initially were nervous about automation: Their very first question was why there were only eight chairs depicted in a conceptual drawing when there were some 16 technologists in the room, Thomson noted. Yet the six reduced positions were eliminated through attrition much earlier than expected, and ultimately many technologists embraced the new system.

After 2 years with total automation, one surprise for Thomson has been how much faster microbes grow because staff access the incubator through a small port, rather than as in the past when they opened the door periodically all day, releasing a little heat and carbon dioxide each time. “In the conventional method, we looked at urine cultures after 14 hours of incubation,” Thomson said. “With automation, we look at urine cultures after 10 hours of incubation.” Also, the workflow is more efficient, he added. Plates are read continuously as soon as they are ready, rather than stacked on a bench and read in batches.

Ledeboer’s lab in Milwaukee, which performs about 800,000 tests each year, has reduced turnaround time by about 15 hours since implementing a version of the WASPLab in 2014 and switching to 24-hour plate reading. “We actually got to the point where we had physicians, quite honestly, who were calling us and saying, ‘You’re screwing up my urine culture. It’s coming back too fast,’” Ledeboer said.

It is difficult to tie these efficiencies directly to patient outcomes, but Thomson’s data show some reduction in hospital length of stay. “It’s an incremental gain,” he said. “You don’t save days but you save hours, and hours make a difference in length of stay.”

Time to Automate, or Wait?

New features are coming soon to total automation systems, according to Jacobs. The manufacturers have already piloted modules that will pick colonies from plates, send samples to mass spectrometry for identification, put up a suspension for susceptibility testing, and read the results. While he embraces automation, Jacobs agrees the current systems are in some ways not a leap forward; they simply optimize what microbiologists already do.

“It still has that delay of 18 to 24 hours of your initial culture growing up on agar plates, and that’s the big technology hurdle that no one’s been able to overcome economically,” Jacobs said. “At the moment it’s a cost issue. You can perform identification and susceptibility testing by PCR, but it would cost hundreds to thousands of dollars per specimen with existing technology. As the technology improves, that cost will come down to where it will be affordable.”

Jacobs, whose microbiology laboratory at UH Cleveland Medical Center processes about 700 samples a day for 11 hospitals and associated outpatient centers and physicians’ offices, implemented BD Kiestra TLA in May 2016. For about 8 years before that, the laboratory used a COPAN instrument for automated plate streaking.

Dallas plans to wait. His microbiology laboratory, which handles hundreds of samples a day and serves a 716-bed hospital system, is prioritizing implementation of molecular diagnostics. The lab also hired a full second shift of technologists to improve turnaround time, rather than invest in automation.

“If you’ve got the money and you already have all your other toys—like matrix-assisted laser desorption/ionization mass spectrometry and a multiplex PCR system—I say go for it,” Dallas said, “but if you don’t have all those other instruments, get that equipment first.”

Laboratories that can afford to automate are likely to recover their costs, advocates say, especially as added features lead to more efficiencies. “Is there a future where molecular testing is going to replace what we’re doing on agar plates?” Thomson said. “I would think so, and I sort of hope so. But there are so many hurdles that must be overcome before we’re even close to that being a potential. … If the payback is three to five years [for total laboratory automation], we’re certainly going to need these instruments over that period of time.”

While early adopters of automation had to make the business case based on labor savings, now there are many more reasons to justify the change economically, Ledeboer noted. “The fact that we’re advancing things like digital imaging really makes the business case much easier,” he said. “We have quality justifications now. We have automated reading justifications, which make it really, really easy.”

Dr. Thomson has received honoraria from BD Kiestra for lectures and expert panel discussions.

Dr. Jacobs has received research grants and/or travel support from Nanosphere, Accelerate Diagnostics, Focus Diagnostics, bioMerieux, Inc., and Beckton Dickinson.

Dr. Ledeboer has received grant support from BD, and has received grant support from and served as a consultant to Copan Diagnostics.

Julie Kirkwood is a freelance journalist who lives in Rochester, New York. +EMAIL: Julkirkwood@gmail.com

Source. Clinical Laboratory News

09.03.2017