Sponsored • Hygiene

Coatings defeat pathogens

Nosocomial infections are dangerous - sometimes having grave consequences.

The German company Schmitz u. Söhne GmbH points out that manufacturers of medical equipment and furniture are challenged to keep germs under control and it increasingly focuses on the hygienic aspects of new and further product developments in its closed design of operating tables and antimicrobial coatings.

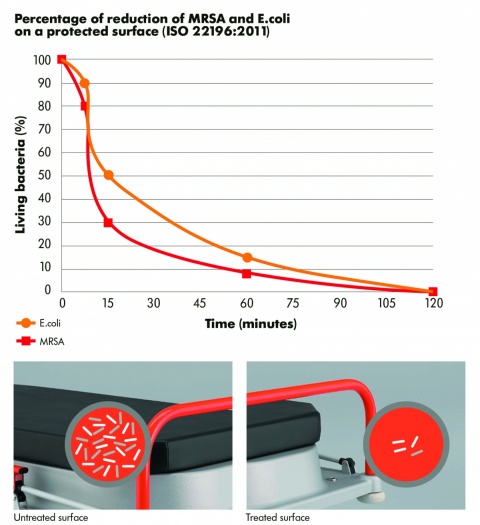

The firm uses such coatings on all frequently touched surfaces, including side guards and push bars of its stretchers. These coatings are based on innovative silver ion technology that effectively and permanently fights mildew, fungi and even resistant strains of bacteria. Studies show that 80 percent of harmful bacteria on the coating can be removed in just 15 minutes and even 99 percent of germs are eliminated after two hours, the company reports.

Pads attached by adhesive gel

Removable pads are generally attached to couches and transport vehicles using Velcro fasteners, which, due to their uneven structure, are extremely difficult to clean. Schmitz u. Söhne use an adhesive gel to attach pads. This is resistant to disinfectants, features an even surface and makes it possible to thoroughly clean the underside of the pad, the firm adds.

Design and construction of OR tables

The design and construction of the company’s OR tables and attachments also have smooth surfaces and a closed design to ensure maximum ease of cleaning. Even critical areas, such as screw heads, are closed or completely covered and, the firm reports, there are virtually no nooks or crannies in which bacteria can multiply undisturbed.

New cleaning shuttle

‘A prime example of a new product exclusively developed for hygiene is the Schmitz u. Söhne cleaning shuttle, which for the first time cleans operating tables easily and thoroughly from the bottom,’ the firm adds. ‘The shuttle consists of a separate, movable frame into which the operating table is placed at maximum height. The supports of the shuttle are positioned directly under the seat section of the table. Afterwards, the staff lowers the operating table again. The chassis lifts off the floor, allowing for thorough cleaning of the underside of the table as well.

Hygiene constantly challenges manufacturers

‘We consider hygiene in hospitals to be one of the most pressing current and future problems in medicine,’ says Friedrich Schmitz, managing partner at Schmitz u. Söhne. ‘That’s why we are doing everything conceivable to control hospital germs and the infections that accompany them. It starts with small details in the design, such as screw covers, and ends with the development of completely new hygiene-oriented products, such as the cleaning shuttle. We will continue to work tirelessly on this issue.’

For more information visit www.schmitz-soehne.com or www.facebook.com/schmitz.soehne

Source: Schmitz u. Söhne GmbH & Co. KG

08.12.2016