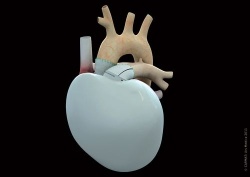

Building human hearts on an assembly line

An artificial heart will be implanted in a patient before the end of 2011, marking a milestone in medicine. The developers are now accelerating plans to manufacture thousands of these mechanical hearts for patients worldwide, reports John Brosky

The International Standards Organisation (ISO) gave the green light this summer to the design and quality processes for manufacturing a fully implantable mechanical human heart.

The financial world is fully behind this bold venture. In one year the share price of Carmat, the Paris-based company that is bringing the artificial heart to market, soared to 10 times its value when introduced in July 2010. The capitalisation for the company on the NYSE-Euronext is currently estimated at €712 million.

Marcello Conviti, CEO of Carmat, said the final step to bring the heart into the operating theatre is the approval of the both the French authority Agence Française de Sécurité Sanitaire des Produits Santé (AFSSAPS) and patient protection committees.

Under AFSSAPS rules, Carmat qualifies for a fast-track approval process because it is bringing forward a new technology. ‘Given the progress made in our project, we are confident we will meet the goal of a first implant of the heart before the end of 2011,’ said Carmat’s CEO.

The firm is expected to receive a further €25 million in August from investors to power its accelerated drive for a commercial launch in 2013.

There is a vast unmet medical need for a mechanical heart. Each year, 100,000 people are diagnosed with severe heart failure and learn they have about 12 months to live as their heart loses its ability to pump blood. Only one in 10 can hope to receive a transplanted human heart.

Frustrated that he could not offer any hope to patients, the world renowned heart surgeon Dr Alain Carpentier spent 15 years developing the Carmat heart (European Hospital, 08/31/2010). ‘The aim of this heart is to allow patients to go from an impossible life -- where they can do just a few steps from bed to armchair -- to a normal social life,’ he said. (EH, 04/26/2011)

Meeting this clinical ambition to help thousands of patients presents a formidable industrial challenge for Carmat and its CEO. The first 20 patients will provide the technical and clinical data required for CE marking and the beginning of commercialisation,’ Marcello Conviti pointed out. Then will come what he called ‘a solid and efficient industrial structure with a second source of supply for all critical components, optimisation of production processes and costs, manufacturing qualification of suppliers, and automation of certain fabrication processes to meet the requirements of commercialisation.’

Finally, the company is accelerating development of the portable peripherals required for patients to move about, which include next-generation, body-worn batteries to extend the autonomy and external consoles to monitor the device's operation either in the hospital or at home.

The peripheral system will be available by early 2012 -- in time for the hospital-to-home discharge of the first recipients of the Carmat heart.

Once implanted, the only external sign that a patient has an artificial heart will be a wire extending from behind the ear to a harness holding the battery, system monitors and wireless connectivity transmitters.

26.08.2011