News • Customer Reference

And still it scans! 15 years of experience with Hamamatsu Photonics NanoZoomer

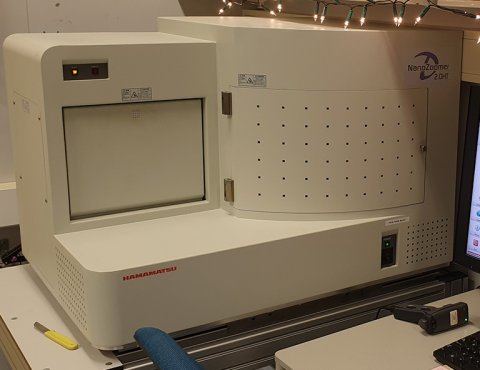

We recently had the pleasure of interviewing Dr. Peter Riegman from Erasmus University. Dr. Riegman is a Molecular Biologist and head of the Erasmus MC Tissue Bank. As an early adopter of digital pathology, Dr. Riegman purchased his first Hamamatsu Photonics whole slide scanner in 2005. It was a NanoZoomer HT, one of Hamamatsu’s very first production units, and it is still in daily use at Riegman’s pathology lab today.

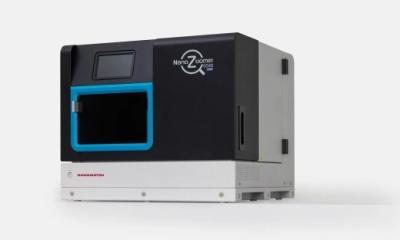

It sits side by side with another NanoZoomer HT installed in 2009 and a NanoZoomer S360 installed in 2019. This trifecta of NZ scanners image 350 slides per day, with the capacity to scan up to 700 slides per day.

Dr. Riegman believes the image quality and service are the two critical elements for successful digital pathology implementation.

Under Dr. Riegman’s guidance, the lab automated slide scanning to comply with routine diagnostic procedures. The lab also provides special stains as a service and this created a unique challenge that needed to be addressed. Through collaboration, Hamamatsu provided a small adjustment to the scanner that enabled Erasmus to distinguish the slide lab labels from the special stain barcode. This relatively minor tuning was critical for fully automated slide scanning and this flexibility within the NanoZoomer design allowed for broader adoption within Erasmus University. Dr. Riegman’s experience with Hamamatsu NanoZoomers illustrates the commitment Hamamatsu has to providing uncompromising digital pathology solutions that provide excellent image quality along with reliability and intelligent, flexible design.

Reliability

Dr. Riegman had the opportunity to compare the image quality of both NanoZoomer HT and S360. He concludes the image quality of HT and S360 are sufficient for routine diagnosis.

A successful digital pathology implementation starts with organizations addressing the unmet needs and reimaging the laboratory workflow to increase efficiencies. At the time of purchase, the emphasis is often on image quality, ease of use, and costs. Upfront costs are easy to understand, but the actual return on investment comes from long-term reliability that maintains consistent slide throughput increasing lab efficiency.

Erasmus MC Tissue Bank operates two older scanners, so how reliable are those scanners?

These scanners do not require a lot of maintenance, contrary to what people may think. At times unexpected things do happen, such as replacing the light unit or filters after many years of overuse. In general, the correction step in HT scanners offset the issues, and the Hamamatsu service engineers can troubleshoot and fix those without noteworthy disruption to the workflow.

Hamamatsu NanoZoomer scanners are built on the foundation and knowledge of over 15 years of product innovation in digital pathology combined with 65 years of photonics experience. Hamamatsu believes in manufacturing and providing the most reliable whole slide scanners in the market. We thrive on product and image quality.

Visit nanozoomer.com to find out more about Hamamatsu NanoZoomer scanners.

Please enjoy the full interview with Dr. Riegman:

Dr. Peter Riegman, Head of the Erasmus MC Tissue Bank, was one of the first NanoZoomer customers worldwide. Actually, the third ever-built NanoZoomer was delivered in 2005 to the Erasmus Institute. When the workload became too much for one scanner, a second NanoZoomer HT was installed in 2009 and in 2019, an S360 was added.

You currently have three scanners: two (very old) NanoZoomer HT and one S360. Both HTs are still scanning – do they still work properly and do you need a lot of maintenance in the meantime?

Not a lot of maintenance, although sometimes unexpected things need to be replaced. For example, the light unit or filters need to be taken out due to the fact the glass fibers that send the light to the stage is worn out and the light changes slightly in color over the many years. This is of no influence to the image quality, because this is corrected by the HT, but the effect finally became out of range for this correction. In addition, computers need to be updated to Windows 10. One done and one to go.

After such a long time, it was to be expected, that the system had to be updated to a new Windows version. Did you face difficulties with the Windows 10 upgrade? Especially with the old HTs?

After installation of Windows 10 on the Windows 7 computer, we asked Hamamatsu for an installable version of the scan software. The question alone was enough for them to completely install everything remotely for us. It works flawlessly since that time.

The repairs do not sound like standard maintenance issues. Did Hamamatsu find the failures quickly?

Yes, the support engineers dealt with failures swiftly as with the repairs.

Things like degrading fibers are surely not the standard repair issues?

The repairs were certainly not standard issues; however, Hamamatsu support asked for the log files, drew the conclusion, and knew what to do.

You have been using the S360 for a year now. How does it compare to the old HTs?

The high image quality of the S360 is comparable with the fine quality of the both HT scanners. Moreover, for the average diagnostics the images are fine. Of course, speed of the S360 is so much faster due to new techniques and much improved logistics in the scanner.

In the past, you used the NanoZoomer HT for research, routine and – as one of the first to digitize their training slides – students’ education. Is that still the main use?

In the past the slow scanners were used for science, education and limited diagnostic applications* like external consulting, panels and molecular diagnostic archive for glass slides needed to be sacrificed for molecular assessments. The S360 is now scanning for diagnostics in general on a daily basis. This way we run tests to enable us to scale up to scan the total yearly production of 250.000 glass slides.

And the HTs? Are they still used for the same applications?

Yes, we use the HTs still for the old applications.

Do you plan to go digital even for routine diagnostics?

Yes. The next step is that we want to add a modern pathology communication program or IMS that makes the scanners communicate with the LIMS so the pathologists are supported in their digital workflow and after that, we scale up the scanning capacity to scan the full production.

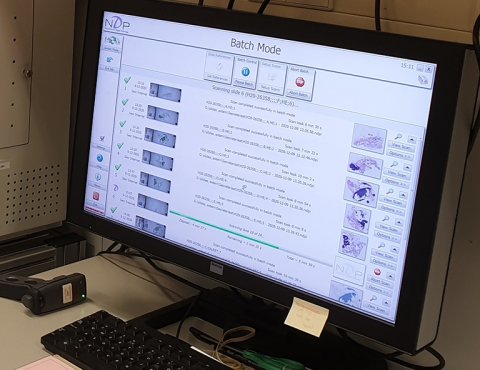

In the beginning, you scanned most of your slides in semiautomatic mode, as the scanner software accidentally identified felt tip pen marks as tissue and therefore did not define the scan area correctly, leading to longer scan times and larger file sizes. With the fast S360, and if you plan to scan your whole production in future, did you find a way to scan all slides in fully automatic mode?

Yes. Especially, for routine diagnostics it is a pre-requisite even to scan fully automatically. We optimized the laboratory for the preparation of slides and logistics, like the labeling of the slides with bar codes. Automatic staining covering and drying of the slides was adjusted. Some adjustments were made on the scanner to distinguish the lab labels from the special staining equipment bar codes that can also be present on a glass slide.

Back in 2005 after installation of the first scanner, its integration in the workflow took time and some modifications by Hamamatsu. Do you still face sometimes problems with compatibility?

We do seem to have a good working logistics in scanning for diagnostic purposes in place and good insight in the needed communication. We now need a communication program or IMS to make the logistics complete to enhance the pathologists’ acceptance level.

Are there functions or features, you would like Hamamatsu to improve or to add?

For the scanner itself it would help if direct access to empty slots for cassettes could be given during scanning without bothering the ongoing process. For instance, a place/chamber where new cassettes could be put in (e.g. max four cassettes at a time) which are added by the scanner to the carousel whenever the scanning process allows that. When the cassettes enter the carousel, inventory is made and priority can be given. In addition, a place/chamber where the scanner puts finished cassettes (e.g. max 4 cassettes at a time) when all slides in the cassette are scanned to satisfaction. This way you create a sort of running belt and decrease personnel waiting and operating time.

* Note: NanoZoomer S360 is CE marked under EU’s In Vitro Diagnostics Directive (IVDD) for in vitro diagnostic use.

NanoZoomer S360 is for Research Use Only in US. For other countries, please consult with Hamamatsu. NanoZoomer HT is for Research Use Only.

29.06.2021