Article • Patient-based real-time approach

PBRTQC: improving quality control in the lab

Implementing patient-based real-time quality control (PBRTQC) protocols within the laboratory testing setting can offer benefits in terms of patient safety and reducing risks. While the concept has been around since the 1960s as a quality control (QC) strategy, it is still not being widely used as a frontline process, according to one of the leading experts in the field, Professor Tony Badrick. He outlined the latest developments in PBRTQC at a symposium at the EuroMedLab congress in Munich in April, examining advances in internal quality control (IQC) tools and techniques in the laboratory.

Report: Mark Nicholls

Introducing the concept and developments in the field, he said there are a number of reasons for using patient results for quality control. While IQC has evolved over time to become an essential part of laboratory process control, PBRTQC models have more recently been investigated as alternatives in the lab. ‘Sometimes other results are unavailable or impractical, or patient results might detect an issue that other forms of quality control cannot,’ said Prof Badrick, who is the CEO of the Royal College of Pathologists of Australasia Quality Assurance Programs (RCPAQAP).

In addition, the state of the testing processes can be assessed between the times of routine control-based QC. The expert explained that QC is a retrospective process and there is little cost, and the sample is commutable.

Understanding patient population characteristics

Image source: Adobe Stock/Dmitry Kovalchuk

Prof Badrick offered some general considerations for implementing patient-based quality control. For example, it can bring insights into the biological and analytical characteristics of certain tests, such as reference intervals, pathological values, and biological and analytical variation. PBRTQC also helps to understand the patient population characteristics served by the laboratory and the capability of the laboratory information system, such as which data can be extracted and analysed. He said: ‘Currently, most laboratories’ QC systems perform a QC sample run once a shift or once a day. There may be hundreds of patient samples between these QC samples, so if there is a problem, a lot of samples must be rerun, and results retracted.’

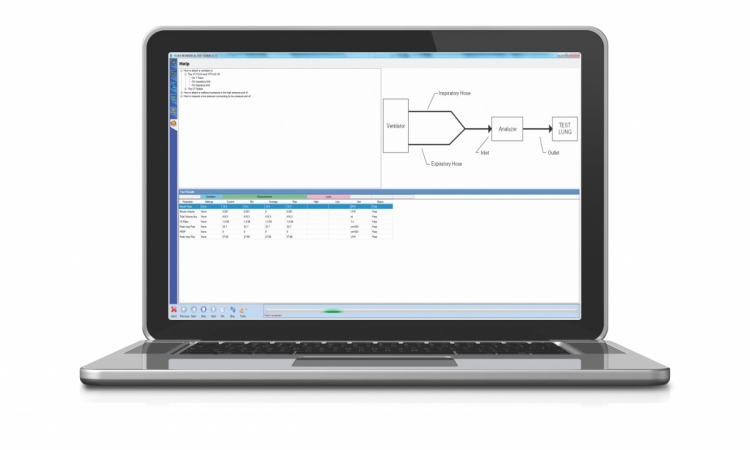

The expert explained how PBRTQC implementation has become more manageable due to recent technological advances. ‘Now we have the IT capabilities and the patient numbers to make it viable,’ he said. ‘The challenges are getting the software to make it work in real-time. This needs to be in middleware or on the analysers.’

The development of better techniques and middleware to allow the practical application of PBRTQC has subsequently led to a rethinking of conventional QC, and the relationship between internal and external quality assessment (EQA), as a process designed to independently assess the performance of methods across laboratories and platforms. With manufacturers now working to adapt software solutions accordingly, the symposium considered the prospects with PBRTQC and how it could be used in conjunction with IQC, or instead of it.

Increased error detection, decreased patient risk

Looking ahead, I believe PBRTQC will become the main form of quality control integrated with some conventional QC on most high-volume clinical chemistry analysers

Tony Badrick

Organisations such as the International Federation of Clinical Chemistry (IFCC) are working to raise the profile of the potential of PBRTQC. The IFCC has produced a series of papers focusing on this area, describing all the steps that are needed to develop, implement, and validate PBRTQC, Prof Badrick added. He said: ‘Labs and manufacturers are being made aware that PBRTQC is now a possibility, and there is an interest from these parties into what is needed to progress this.’ Looking ahead, the expert said: ‘I believe PBRTQC will become the main form of quality control integrated with some conventional QC on most high-volume clinical chemistry analysers.’ Envisioning clear benefits for clinicians, hospitals and health systems, as well as patients, he continued: ‘PBRTQC provides better QC and hence less likelihood of errors not being detected. This should reduce the risk for patients. In addition, there would be reduced cost for labs with QC, leading to better comparability between labs.’ The Munich symposium also included presentations on how conventional QC is practised and how can it be improved; the importance of demonstrating the commutability of reference materials with IQC; and implementing PBRTQC into routine practice.

16.06.2022