Multi-dimensional planning is the future

Econometric 5-D hospital modelling optimises workflow

Hospital refurbishment or new buildings can quickly run into several million euros.

Thus financial managers first need to assess whether theoretical plans realistically marry with future practical needs in daily hospital life, such as best patient care, resources and utilisation, avoidance of down and waiting times, under and over capacities, and whether the project will pay off. ‘With all these considerations, a simulation of treatment processes, using a virtual building model, can help,’ says Dr Michael Küpper, MD of M+management GmbH in Munich, a firm offering this procedure. Computer modelling facilitates various models and opportunities being run through until the best solution is found.’

What if?

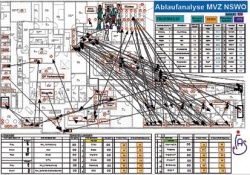

The computer simulation proceeds according to the VAO method: Visualising, Analysing, Optimising. Parameters such as patient and staff facilities, operating theatres, recovery and waiting rooms, beds, equipment etc. are modelled onto a scaled plan of the new building. Using special tools, the typical processes, times, durations and costs are defined and distances are traced in the model. External data, such as examination and surgery times, work rotas, appointment diaries, and more, can be accessed via an interface. These parameters are then animated and simulated using the hospital data. Initially, the result is a realistic evaluation of the status quo. Potential problem areas and weaknesses can be recognised and compared with reference data.

The procedure

- Objectives and target figures are determined and processes analysed

- The relevant patient groups and their movements are recorded with the corresponding data through talks with doctors and nurses

- Data preparation (new data collation or adaptation of existing data through clustering for instance)

- Visualising, verifying and validating of actual processes in flow diagrams

- Creation of simulation models

- a. Animated simulation of actual situation

- b. Animated simulation of target situation with actual processes

- Workshop on fine tuning of processes and results – identification of optimisation approaches

- Data transfer into an abstract space and function programme

- Adaptation/optimisation of layout planning

- Creation of optimised simulation model in a 3-D building model

- Animated simulation of the new target situation with target process to check spatial planning (of existing versions)

- Animated simulation of different future scenarios, such as with increased patient numbers

Example: Planning a day clinic construction

Patient processes are established in the shape of swim lane flowcharts, where the competencies and rooms are shown. Patients requiring the same type of procedures were clustered. The processes shown were transferred to the planned layout of the Day Clinic and entered into the simulation model (diagram 1). Evaluation of the simulation, based on the actual data, confirmed the real, existing waiting times for patients as well as the capacity of rooms on one working day. Increasing resources did not result in further improvement. However, optimisation led to a significant increase in patient stays and waiting times. The average patient’s stay in the clinic can be cut from almost three hours to 35 minutes. The new building should also be able to cope with patient numbers increasing by 15%, as seen in recent years. This is why the preferred type of planning was an approach where computer simulation ensured that the planned geometric structures, as well as the number of resources required, harmonised with the processes. A simulation model with actual processes was designed based on a revised construction layout with the affected functional areas. (See diagram 2 for result of simulation run with the target data.) Thus it was possible to cut staff movements by around 50%, and running costs could be reduced due to cutting down on excess capacities.

Geometric and functional structures in the building data model

Changing target values (patient numbers, waiting times, room sizes, resources utilisation) results in prioritisation of the spatial allocation of floor space in the computer model. The objective: Reducing distances and staff movements, patient waiting times, increasing throughput and cutting down on facilities required. In this way, staff movements in the day clinic were cut from 85km a day to 40km a day, equipment utilisation was increased from 65% to 85% and the energy requirement was cut from 380kWh/ m2 to 260kWh/m2 a year. The implementation of the target result data (target values) and the surface space from the room and function programme into a digital building model facilitated the calculation of building costs required for planning and running costs. As a result of the optimised space and creation of efficient geometric structures, building costs for the current example were reduced by 15%. ‘Planning a building on a digital, virtual model puts an end to halfknowledge and isolated solutions. Our solution is a central data set with all relevant data used to design and run a building holistically, economically and with a look to the future. Multi-dimensional planning is the future – and nothing is as sure as the future,’ explains Dr Klaus Kühn of M+management GmbH the 5D Hospital model.

Details: www.mplusmanagement.de

After studying architecture in Stuttgart, Dr Michael Küpper became a planner in architecture practices in London, Hamburg and Munich. Since the mid-1990s he has focused increasingly on hospital planning, initially as a freelancer for project management in hospital construction for a Munich engineering firm. In 2000 he became a Managing Partner of M-management GmbH, which specialises in healthcare projects.

26.04.2013