The OptoLabCard

Spanish researchers develop a new lab-on-a-chip for 20-30 minute tests. David Loshak reports

Researchers funded by the European Union have devised OptoLabCard, a system that prepares samples and performs DNA tests on bacteria in a portable, easily used, cost-effective lab-on-a-chip.

Within three years, this work will lead to commercially available hand-held devices that detect bacteria in the food chain and diseases as diverse as cancer, hepatitis, AIDS and flu within 20–30 minutes, replicating laboratory processes anywhere at any time.

OptoLabCards could also be used to identify pathogens and pollution in water supplies, says Dr Jesús M Ruano-López, coordinator of the OptoLabCard project at the IKERLAN Technology research centre, Arrasate, Spain. The company develops products that combine mechanical with electronic and software engineering.

Clearly, the quick detection of diseases such as campylobacter and salmonella well before they enter the food chain would greatly enhance food safety, especially as tests on farms or in food processing and distribution require laboratory testing that can take days.

The notion of a device small enough to perform tests normally needing lab facilities arose from the development in the last century of microelectromechanical (mems) technology, which made it possible to put sensors, fluid channels and optical components into a tiny space, using components measured in microns (millionths of a metre).

But until now production costs have been prohibitive. What distinguishes the OptoLabCard is the material used to manufacture the components and the way in which samples are prepared for testing.

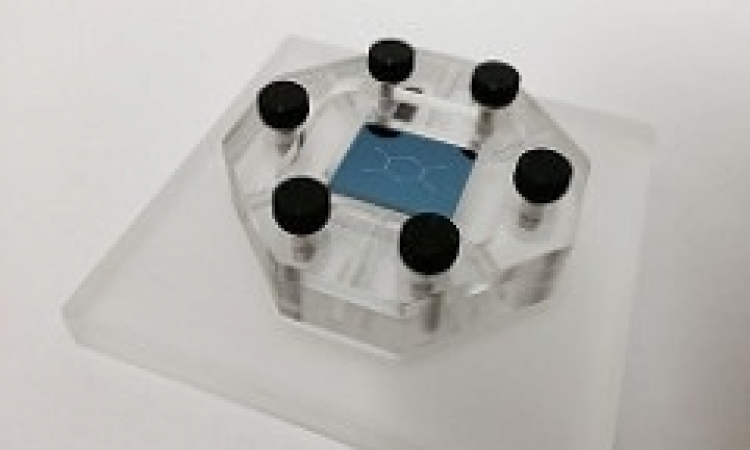

The device integrates optoelectro-nic, microfluidic and microbiological advances. Chips are simpler and cheaper to produce because, for most components, the OptoLabCard uses a negative thick photoresist – photosensitive resin that loses its resistance to chemical etching when exposed to radiation and used in the transference of circuit patterns to semiconductor chips when making integrated circuits.

The base unit contains all the electronics and optics and the chip is disposable. Incorporating sample preparation into the chip enables users to perform laboratory processes wherever they need.

‘Sample preparation is the crucial part but it was abandoned by earlier developers,’ Dr Ruano-López notes. ‘After all, to detect the presence of bacteria you must have a reliable sample.’

Rubbing a swab across a chicken carcass, for example, might produce a sample containing as few as ten bacteria, an amount that could go undetected once transferred into the device.

That inability to provide a representative sample could mean the bird, or even the entire batch, being deemed clean even though covered with pathogens.

To overcome that problem and improve the accuracy of detection, Ikerlan incorporated magnetophoresis and the polymerase chain reaction (PCR) technique to concentrate samples before testing, PCR being well-established as a method of replicating DNA to create higher concentrations.

‘In that way we can create more concentrated bacteria samples,’ Dr Ruano-López explains. ‘And because it works with DNA, the same device can be used to detect many types of bacteria and diseases.’

Campylobacter detection will be especially important, as the bacteria are highly prevalent in poultry, leading to gastrointestinal infections costing $1 billion to treat in the USA and Europe annually.

01.09.2008