Building quality

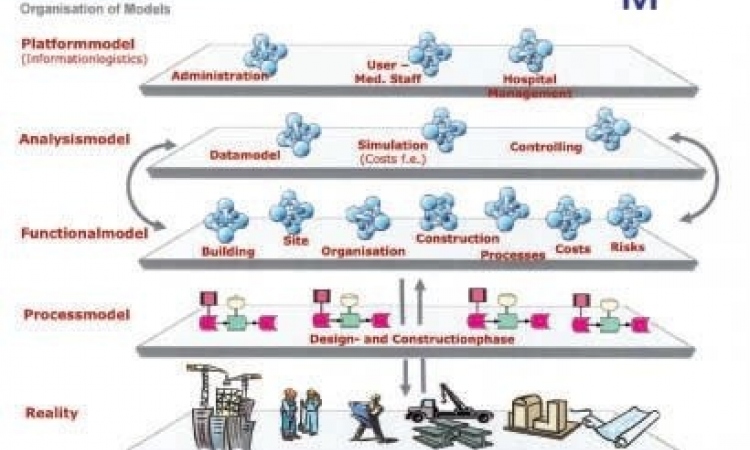

The Digitally Verified Clinical Concept 2015

Being involved in a €68 million newbuild and renovation project for the Riesa Elblandklinikum Riesa near Dresden, the privately held firm Unity AG developed a project management scheme customised around the hospital’s assets and needs, and also produced a digitally verified clinical concept to optimise building and renovation activities in advance. Prior to this project, Unity AG had mainly gained experience in industry. When Bettina Döbereiner interviewed Meik Eusterholz, Project Manager of Unity AG, she asked why he had mentioned ‘getting a bloody nose’ when the firm first became involved in the healthcare sector.

‘Seven years ago,’ he explained, ‘when we began to transfer our experiences from industry into the healthcare sector, we had critical discussions with experts who would not accept any comparability, saying a hospital was not a “disease plant”. Since then the mindset has fundamentally changed, recognising the general tasks of patients’ well-being and employees’ working contentment.’

So, today, what are Unity’s objectives for itself and what guarantees can it give to a client?

‘With process management, for example, waiting periods can be reduced and operating theatre pass-through times can be optimised. We’d like, for example, to see increased case numbers per operating theatre with the same amount of resources.’

Where might the hospital gain the most?

‘Before implementing changes of processing in an organisation, it had better be checked computationally thereby avoiding faulty planning and unwelcome surprises. In this case, the digitally verified hospital ensures the overall possibilities of the building project and, investment costs as well as running costs can be reduced.’

What data basis is used to determine the actual state of the Elblandklinikum Riesa project?

‘As a planning guide we take the data from the in use IT-systems, such as the HIS, or patient transportation software and others. In a sense, we take a look in the rearview mirror in order to empirically assess, for example, on what days and at what times patients frequent the emergency room.’

How was the target state worked out?

‘On the one hand, the target state has been discerned with the help of the identified potentials, i.e. weak points (amounting to about 400) and, on the other, in close cooperation with the staff and management. If, for example, there will be more minimally invasive surgery in the future, this will clearly affect operating theatre cycle-times.’

Did Unity develop the analysis and simulation software, or where did it originate?

‘We’ve used standard software, e.g. Siemens plant simulation, for over ten years, to visualise complex production networks. With the software originally designed for material flow, we had to extend it for our own clinical purposes. So we developed simulation modules in order to effectively visualise each and every clinical process comprising emergency room, the therapies sector, surgical sector and discharge.’

You called this project unique for Europe; is it?

‘Yes. As far as we know there were similar projects only in the US, where simulation methods were used for project planning.’

Did those projects serve as your models?

‘No. We have learned from our own projects within radiotherapy and operating theatres. Having used simulation for industrial construction planning as standard for over more than ten years, the gain was obvious from applying that simulation to this kind of building project also.’

For you personally, what is most rewarding from this hospital project?

‘The Elblandkliniken serves as an innovative partner for this particular project. All stakeholders are enthusiastic and very cooperative. The fantastic commitment of the staff is especially rewarding! Added to these is the great public interest.’

19.12.2011