Healthcare needs automatic identification data capture

We are used to barcode scanning in supermarkets, our luggage being barcode tagged at airports and much else, yet in healthcare the use of Automatic Identification Data Capture (AI DC) technology – such as barcodes or Radio Frequency Identification (RFI D), is still rather rare, says Christian Hay of GS1* Switzerland.

‘For a number of years, care providers have been addressing the reduction of errors, which result in increased costs, a lower quality of life for patients and, in quite a number of cases, patient deaths,’ Christian Hay explained, pointing to why healthcare needs automatic identification data capture (AIDC). ‘Actions taken began with the investigation of processes, with process compliance issues, etc. and they now increasingly focus on the “right product for the right patient”. AIDC can serve to ensure this approach: a secure supply chain means that, prior to handling an individual patient case, the staff is aware of what is on the shelf, what has been ordered, and what can be delivered – enhancing patient safety.’

How should processes be engineered?

‘In a hospital kitchen warehouse, if nurses are in a position to choose the type of biscuits for patients in their ordering process, they will all choose vanilla – leaving coffee and chocolate biscuits to run over the “use by” date. Aspects such as these matter in healthcare. If the staff orders a medical device and pertinent processes are just as flexible as in the case of biscuits, something is seriously wrong. Order and delivery processes should be implemented in a way that eliminates interpretation, regardless of the type of product. IT support is necessary to achieve that, not only to eliminate human interpretation, but also to secure appropriate documentation and traceability.’

What are the current technological approaches?

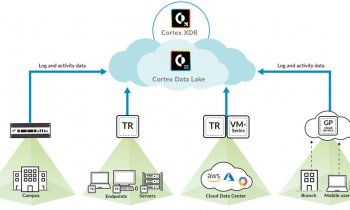

‘Securing the supply chain involves AIDC. Across the world, manufacturers of medical devices materials have reached the consensus that their labelling should be standardised globally, and oriented towards user needs. Implementation initiatives have started in countries such as the Netherlands, France, Canada, and Japan, to deliver products to market with labelling based on the GS1 system of standards, leveraging experience from other industries. We mostly see now linear and 2-D barcodes, which offer the users the necessary information in the appropriate format.

What are the potentials and challenges of RFID?

‘Some projects have been launched to gather experience on its use. The technology offers promising potentials, such as temperature control for the cool chain, transparent data capture that eliminates the need to point a scanner to the item, and the capacity to read from and write information on the tag as well as to reuse it. Not every type of tag will meet all these features; more sophisticated tags come at a price. Frequencies have been standardised, but still present technical challenges: not every reader can activate every frequency. ‘Barcode technologies are recognised as the best possible training ground. Once the IT systems can work with data captured from standardised barcodes, they will also be ready to manage data acquired from RFID tags. The first technology is dramatically less expensive than the second, and the number of barcoded products delivered to healthcare providers is already considerable. Labelling the remaining items should require fewer and fewer resources.

‘RFID in healthcare is mostly proposed for three frequency bands: low (~135 KHz), high (13.56 MHz), and ultrahigh (868 MHz in the EU). A few years ago, publications suggested potential interference between RFID readers and medical equipment; this created uncertainty about its safety for use. Strong consensus has been lacking as to how interference should be measured. Modern medical equipment is better protected against radio frequencies than older prod-uct generations, but older equipment is still in use. International standards about the testing conditions are being revised. ‘In the meantime, RFID solutions should be taken into account in cases where they add real value compared to barcoding. This is the case for hardware tracking – for patient beds, and mobile equipment; for applications where information about use and maintenance is written on to the tag; for automatic vehicles distributing products on the hospital campus, where the delivery point can be encoded in the tag; as well as for medical textiles, where the user ID is recorded in the tag, for use by the dispensing robot.’

Which criteria are key to future- safe implementations?

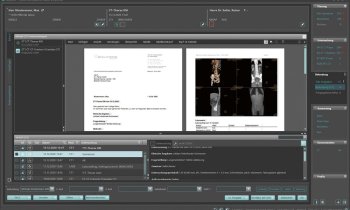

'When working to automate processes in healthcare, decision makers should define the required technology based on the process re-engineering concept. The user needs to consider current good practices, which include using the data carrier and data as a pointer to database information, not as a “full book” with static information. Good practices in other industries show that the highest degree of interoperability is achieved when standards are respected stringently. Interoperability implies that hospital IT will be capable of utilising and managing information captured from labels on products from manufacturers and suppliers, as well as from labels on items produced or reprocessed in the hospital, in central sterilisation, for example.’

* GS1 is an international not-for-profit association that develops and implements global standards and solutions to improve the efficiency and visibility of supply and demand chains internationally, as well as across multiple sectors. With GS1 organisations in over 100 countries, the association’s system of standards, which include barcodes, eCom, GDSN and EPCglobal (using RFID technology), is considered to be the most widely used supply-chain standards system in the world.

PROFILE

A specialist in AutoID & eHealth, with extensive experience in the field, Christian Hay has held key positions in renowned organisations. His present role at GZ1 Switzerland is Delegate Healthcare. He also teaches healthcare logistics at the University of Applied Sciences in Berne.

12.11.2012